Tungsten and Gold-Plated Tungsten Wire as Alternatives to Precious Metals

According to research by Evaluate Ltd., annual R&D spending by the global medical technology industry is projected to reach $39 billion by 2024. Innovations in “medtech” can mean anything from creation of new disposable devices or health-related IT to improvements in equipment, surgical procedures, and biomaterials.

The global medtech industry is expected to grow 5.6% per year between 2017 and 2024, for total sales of $595 billion in 2024. That’s good news for the manufacturing sector, for device makers, and for the suppliers that serve them.

But while the highly competitive marketplace means big opportunities, it also means medical device design teams are often racing to reduce time to market, which means somewhere, something (hopefully not someone) may be compromised.

Challenges in Material Sourcing

In practice, competition can mean that medical device manufacturers are often squeezed into subpar sourcing relationships because of shrinking deadlines and budget allocation constraints.

For example, minimally invasive and diagnostic devices, as well as drug delivery and life support systems, often require raw materials including specialty or precious metals. Not only are these materials subject to speculative pricing — a surefire way to deplete a budget — but also many of them are considered conflict metals and require scrupulous validation.

Yet, some devices simply require an incomparable level of radiopacity that is only available in precious metals like gold. In fact, gold is often found in drug delivery systems and stents because of its combination of high resistivity to bacterial colonization and its radiopacity.

Substituting Tungsten for Precious Metals

So, how do manufacturers produce quality devices efficiently and on budget? One way is to build good, strong relationships with experienced, innovative contract partners and suppliers.

Did you know, for example, that there are cost-effective alternatives to metals such as gold, platinum, and palladium? Hopefully, your sourcing partner does.

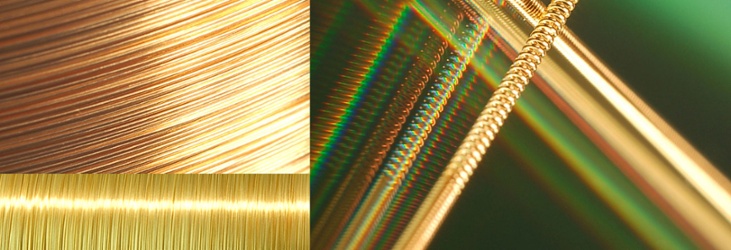

In applications where material toughness and radiopacity are crucial, tungsten has become an attractive alternative. This is due to the many advantageous properties of tungsten, including:

- A density equivalent to gold

- A comparatively high tensile strength and mineral hardness

- A low vapor pressure at high temperatures

- The highest melting point of any metal

Using Tungsten in Medical Applications

Together, these characteristics make tungsten strong, radiopaque, virtually heat resistant, and, when alloyed, flexible. As a result, it is currently used in a variety of medical applications.

For instance, tungsten is regularly incorporated into polymers for high visibility catheters. It can be expertly machined into close tolerance tungsten pins and rods for use in dental and medical applications.

Because of its low coefficient of thermal expansion, tungsten is often used to create a bond with glass having a similar coefficient of thermal expansion. This allows tungsten to be used in hermetically sealed assemblies powering a wide range of medical devices.

Advantages of Gold-Plated Tungsten Wire in Medical Applications

In addition, for some of the added radiopacity of pure gold, tungsten wire is sometimes plated with a very thin layer of gold. This imbues gold-plated tungsten wire with radiopacity properties similar to those of platinum/iridium, but at a much lower cost; the gold plating increases the wire’s resistance to corrosion.

This gold-plated tungsten wire is often used in cauterization applications, guide wires, and probes used in deep brain studies. Besides offering opacity and corrosion resistance, the gold-plated tungsten wire still has many of the beneficial properties of tungsten, including:

- Strength at very small diameters

- The ability to maintain the wire’s straightness and shape under a range of temperature conditions

Partnering with a Knowledgeable and Trusted Material Supplier

With the medtech industry likely to continue allocating funds to R&D in the years to come, the question is, does your team have the quality sourcing relationships needed to bring your concepts to market?

While tungsten is not always an appropriate substitute, your material supplier should have a thorough understanding of how, when, and what composition would be the right, cost-effective alternative solution to your precious metal predicament. In an era of one-stop-shopping, many suppliers also offer secondary capabilities such as precision cutting, grinding, machining, and surface treatments like passivation and sandblasting.

Remember, since tungsten — like gold — is considered a conflict metal (as per Section 1502 of the Dodd-Frank act), your supplier should comply with all U.S. regulatory standards, have a quality system in place, and provide traceability and metrology.

As biomaterials continue to evolve, manufacturers expect their contract partners to evolve with them. That means not only providing a quality product, efficiently and at competitive prices, but also staying informed and bringing experience and innovation to the material sourcing process.

To learn more about tungsten wire and its potential benefits for your application, request Metal Cutting’s free guide to the basics, Tungsten Wire 101.