Metal Cutting has over 200 mechanical polishing machines running on a continuous, lights-out schedule. We have carefully crafted recipes that combine time, temperature, action, fluids and abrasives in order to yield consistent and specialized custom metal polishing results—regardless of quantity or part size. Our custom metal polishing services have the capacity to improve the surface finishes and edge radii of your metal parts. And, as customers ask for new or unique finishing requirements, we custom create new recipes, always focused on meeting your unique requirements.

Custom Metal Polishing Process and Capabilities

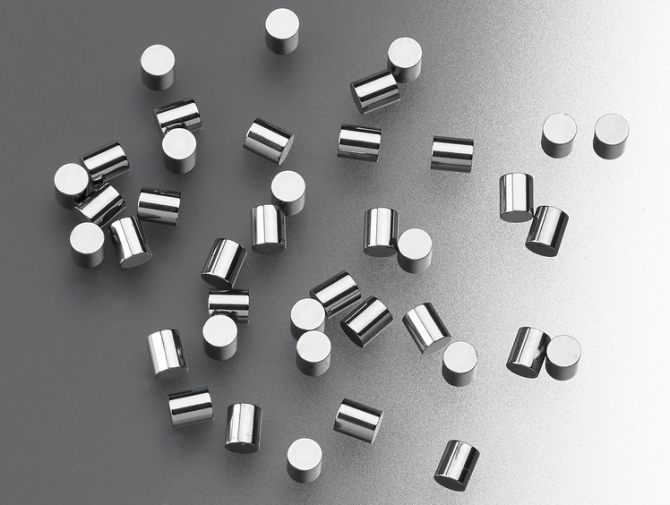

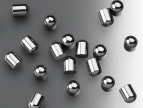

Our metal polishing process ranges from multiple ultrasonic frequencies to extremely vigorous centrifugal high-speed motion and everything in between. We offer 24/7 around the clock finishing capabilities using multiple machines to provide an infinite capacity. We utilize finishing equipment with a range of amplitude and frequency to achieve differential results. We have experience with multiple suspension fluids to execute uniquely lubricious polishing. Our abrasive media and powder span all shapes, types and formulations including proprietary metallic media we manufacture ourselves.

Drawing on our extensive custom metal polishing experience using abrasive methods in manufacturing, we have been able to achieve specialized finishes on a variety of metal shapes and surfaces, all to customer specifications.