Precision Metal Cutting for Tight Tolerance Specifications on Critical Devices

At Metal Cutting Corporation, we are precision metal cutting specialists, manufacturing burr-free tight tolerance parts from all metals. We provide the precision required by medical device, electronic, automotive, biotechnology, semiconductor, aerospace, fiber optic, electrical, and many other diverse industries that demand perfection.

50 Years of Experience

We have 50 years of experience with custom metal cutting, grinding and lapping, metal polishing, and precision machining of metal parts. Our expertise, manufacturing capabilities, and inventory of tubing, rod, and wire provide the skills and capacity to meet the needs of high-technology device manufacturers. Specialty metals, micron tolerances, low and high volumes, complex metrology, metal finishing — all these and more are the requirements we meet every day for products shipped worldwide.

Our Capabilities in Custom Metal Cutting Services

Metal Cutting’s capabilities center on our years of experience and our dedication to mastering the complexities of custom metal cutting, including grinding, lapping, finishing, polishing, and machining. Our team is skilled and knowledgeable in our complete range of services, utilizing state-of-the-art equipment to produce precision parts that meet tight tolerance specification — ensuring that your final product meets requirements for both functionality and cost effectiveness.

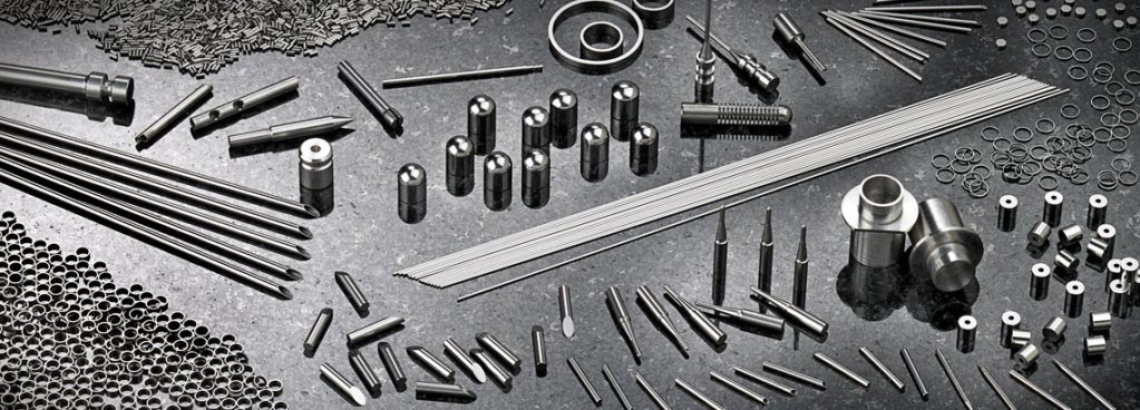

Our Product Portfolio of Precision Parts

At Metal Cutting Corporation, we understand that your success depends on precision and perfection in every part. Our product portfolio showcases more than just the breadth of our capability; it represents over 50 years of experience meeting the exact requirements of our diverse worldwide customer base.

Our Tungsten & Molybdenum Products

Tungsten and molybdenum were the first metals we cut, ground, lapped, and polished — and today at Metal Cutting we continue to build our expertise in these specialty refractory metals, offering tungsten and molybdenum wire, rod, and ribbon products in a range of compositions, sizes, and finishes, as well as high-performance electrodes for resistance spot welding and die sinker EDM applications.

From the Blog

5 Interesting Facts About Tungsten

With Metal Cutting’s long history of supplying and manufacturing high-grade tungsten materials, we’ve developed a special appreciation for the element and what it can do. So just for fun, we thought we’d take a look at some of the more interesting facts about tungsten.

Featured Whitepaper

Learn the Basics of Tungsten Wire, its Properties, and its Applications

Even though tungsten wire’s widespread use has faded with the growing popularity of CFLs and LEDs, it continues to be a product that has a large number of diverse applications. In this free guide, find out why tungsten remains one of the most widely used refractory metals.

Metal Cutting makes it easy to get the custom precision metal components you need. Contact us to get started.

89 Commerce Rd Cedar Grove, NJ 07009

973 239 1100 sales@metalcutting.com

sales@metalcutting.com

Copyright © 2026 Metal Cutting Corporation

Core Capabilities

Precision Cutting

Grinding & Lapping

Polishing

Machining

Finishing