Why Combine Two Elements with the Exact Same Density?

Admittedly, our subtitle is a bit misleading. It is true that by a quirk of nature, gold and tungsten have identical densities. However, the two also have radically different mechanical properties, including their respective melting temperatures.

The most common situation in which gold and tungsten are combined is when gold is plated onto tungsten. Because gold is so expensive, the plating is often very thin — generally, as thin as possible while remaining functional for the application.

But, why would anyone want to plate tungsten with gold except for nefarious purposes?

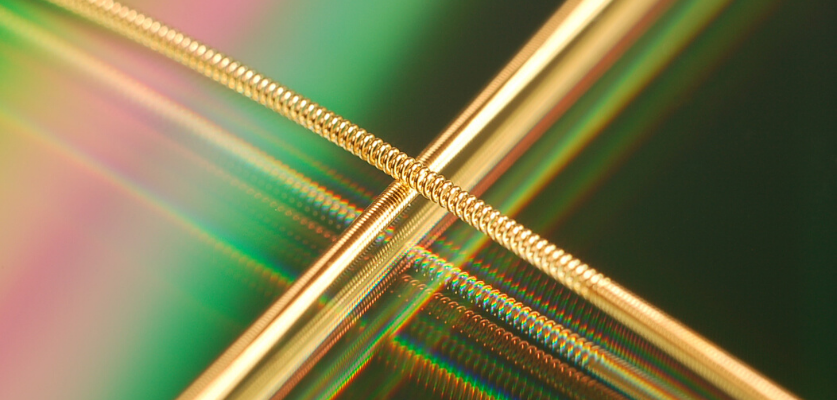

Gold-Plated Tungsten Wire for Controlled Electrical Discharge

The most popular — and legitimate — application for gold-plated tungsten is as a corona discharge wire used to produce controlled electrical discharges in filtration and printing, as well as a variety of other processes.

In addition to its use in air ionizers and in printing/photocopying, other interesting commercial and industrial applications of corona discharge include the following:

- Removal of unwanted electric charges from aircraft surfaces

- Manufacture of ozone for oxidation use

- Sanitization of pool water

- Scrubbing of particles from air conditioning systems

- Removal of unwanted volatile organics (such as pesticides, solvents, or chemical weapons) from the atmosphere

- Surface treatment of polymer films for use with adhesives or printing inks

- Production of photons for Kirlian photography film exposure

- Electrohydrodynamic (EHD) thrusters, lifters, and other ionic wind devices

- Nitrogen laser

- Surface treatment for tissue culture (polystyrene)

- Ionization of samples for mass spectrometry or ion mobility spectrometry

- Solid-state cooling components for computer chips

Contrary to what you see in the old Frankenstein movies, the key to effective corona discharge is control — and gold-plated tungsten wire has proven to be very effective for precise, high repetition cycles where every discharge needs to be the same.

Combating Fine Particulate Matter

With the continued and growing worldwide concern about air quality, the global standard for acceptable fine particulate matter in the atmosphere is driving the demand for tungsten wire filament in air filtration systems.

This particulate is commonly referred to as PM2.5, meaning particulate matter (PM) with a diameter less than 2.5 micrometers (μm), or about 3% the diameter of a human hair. In addition to reducing visibility and creating a haze, elevated PM2.5 levels are a general health concern and are potentially dangerous for people with breathing and heart problems, children, and the elderly.

Clearing the Air with Gold-Plated Tungsten Wire

To combat PM2.5 air pollutants, gold-plated tungsten wire is often used in air ionizers, sometimes also called negative ion generators. These devices use high voltage to electrically charge air molecules to attract airborne particles and thus purify the air in the surrounding environment.

Most commercial air purifiers are designed to generate negative ions (anions). Airborne positively charged particles are attracted and “stick” to the ions, in an effect similar to static electricity, and are then passed through a filter.

In addition, air ionizers are sometimes used in electronic work environments to reduce or eliminate the buildup of potentially damaging static electricity on insulators, conductors, and other equipment.

Tungsten Filament Wire in Printing and Photocopying

Using corona discharge to generate charged surfaces is also vital to electrostatic copying and printing. Gold-plated tungsten wire plays a special role in the corona discharge process in printers and photocopiers — namely, affixing the ink to the paper.

In general terms, most plain printers and copiers use electrostatic charges on a light-sensitive photoreceptor to attract and then transfer toner particles onto paper in the form of an image. Then heat, pressure, or a combination of the two is used to fuse the toner to the paper.

The electrostatic charges within a photocopier are produced by using tungsten filament wire in the corona discharge process.

The Gold Standard for Print Quality

Although unplated, electropolished tungsten wire can perform the same fundamental physical task in printing and copying, gold-plated tungsten wire is literally the gold standard for the corona discharge process in these applications.

Because it dramatically reduces the incident of defects that are viewed as small dots on the paper’s surface, gold-plated tungsten wire results in better print quality. So, for high-speed printing and copying, gold-plated tungsten wire helps to keep image quality neat and crisp.

More Than a Veneer of Quality in Medical Devices

In a completely different field — medicine — plating of the wire with a very thin layer of gold allows tungsten to be substituted for precious metal wire in important medical device applications, providing quality at a lower cost.

In an age of extreme cost consciousness in healthcare, the use of pure precious metals such as platinum/iridium can be prohibitively expensive, especially for single-use devices. For example, the traditional approach of adding 10% or more of iridium to platinum is an expensive method of achieving strength.

As an alternative, tungsten wire provides the necessary strength to meet or exceed that requirement, and the addition of gold plating increases its resistance to corrosion, among other beneficial properties.

Added Benefits of Gold-Plated Tungsten Wire

Round tungsten wire can be made to remarkably small diameters — well smaller than even the current needs for medical devices — or made into ribbon that can be produced very thin. These wires and ribbons can then be plated with gold while maintaining tungsten’s unique advantages in the form of wire and ribbon.

In addition, gold plating provides substantial economic advantages for fluoroscopy applications. The combination of these two dense materials — tungsten and gold — in the form of gold-plated tungsten wire delivers radiopacity properties similar to those of platinum/iridium, but at a much lower cost.

Both tungsten and gold-plated tungsten wire excel in a growing range of applications, in electronics, medicine, and general industry.

To learn more tungsten wire and many of its other unique and interesting uses, download our free guide to tungsten wire properties and applications.