On the spectrum of precision metal cutting methods, it’s easy to understand the allure of laser cutting.

Versatile and precise, it produces tight tolerances and small kerfs. And thanks to science fiction, there is a natural fascination with the idea of using a highly focused beam of light to melt, burn, or vaporize materials such as metal.

So, are there compelling advantages to using a laser method for 2-axis cutoff applications?

In general terms, laser cutting machines range from large, powerful, and aggressive to small, slow, and precise.

Large power lasers make fast cuts, but produce rough end cut surface finishes and wide heat- affected zones. Lower power lasers cut with much less damage to the metal, but take noticeably longer.

Let’s look at some of the advantages of laser cutting.

With laser cutting, the laser beam does not wear out during the cutting process. And since there is no degradation of the cutting process, the results can be easily and accurately repeated.

On thin metal, lasers can cut precisely, with tolerances as tight as ±0.001”. However, lasers are capable of being used with many materials and thicknesses.

So what are the downsides of laser for metal cutting?

Cutting thicker materials requires a more powerful laser, which produces a rougher finish. Therefore, metal cutting with a laser is not ideal when you need to cut a material thicker than 0.5”.

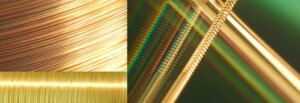

Also, laser cutting of metal is not well suited to highly reflective metals such as aluminum, brass, or copper. The heat produced with lasers is intense, so the laser must be carefully set, monitored, and adjusted to prevent heat stress damage to the workpiece.

It’s also worth noting that the large amounts of energy lasers consume can significantly add to operational expenses.

With laser cutting, materials must be cut one at time and cannot be bundled together to achieve multiple cutoffs. That makes laser slower and more expensive than other precision metal cutting methods.

So, is laser cutting worth the allure?

For 2-axis cutoff, the cost of laser cutting in time and money is often more than can be justified, especially where other methods can produce excellent results at a better price.

Deciding whether laser is your best precision requires an in-depth understanding of your unique application and parameters, and costs compared to other metal cutting methods.