Improving Wear Resistance in Catheters and Other Devices through Swiss Machining Small Parts

Bushings have an array of uses in medical devices ranging from hospital beds to prosthetic joints. In general, these bushings:

- Serve as spacers to prevent metal-to-metal contact

- Reduce friction between metal components

- Ease the movement of reciprocating parts in low-speed applications such as patient lifts

But, did you know there are custom bushings that are Swiss machined for use in some high-speed medical device applications?

Ultra High-Speed Devices

You might not think of medical devices as functioning in ultra-high revolutions per minute (RPM). However, there are a few interesting applications where design engineers have achieved the therapeutic purpose of a device through a design that makes use of a very high rotational speed.

The delivery of high rotational speeds in medical and dental applications can range from dental drills to atherectomy devices used to cut plaque out of blocked arteries and veins in the legs.

In dental applications, the power transmission is relatively simple. In vascular applications, the rotational action achieves the therapeutic effect; however, this action can cause significant wear on the delivery device.

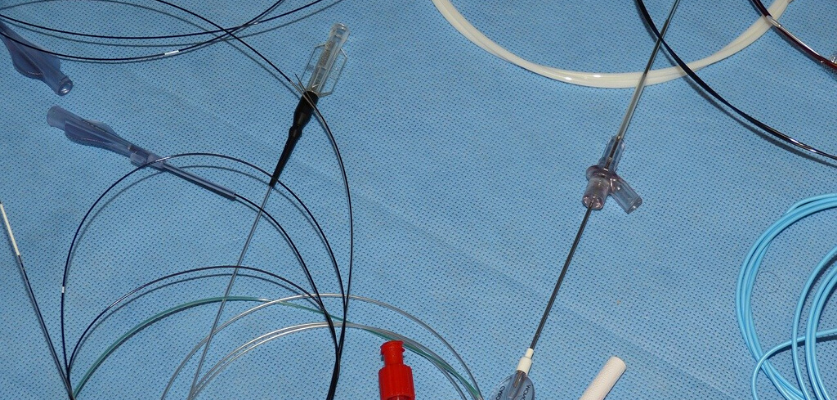

Various types of medical catheters utilize a very high RPM function in the tiny confined space at the tip of the catheter. This creates a failure point unless a specialized, highly wear-resistant component is added to the design.

And that is precisely where tiny metal bushings enter the picture.

Custom Bushings for Catheters and Atherectomy Devices

When a device is subject to high RPM or other forces that can cause it to fail, bushings — although seemingly very simple — are critical to preventing the failure of the device during a procedure.

That is why metal bushings are sometimes used at the tip of catheters and similar devices when the tip must rotate at a high speed over a guidewire. The tip allows for less wear on the end of the catheter or device.

For instance, thanks to our small parts machining capabilities at Metal Cutting Corporation, we are able to make custom bushings for an atherectomy device that is designed for use in treating PAD (peripheral arterial disease), as well as for some cardiac applications. Although the device spins at a very high RPM, the bushing at the tip helps to prevent wear and damage to the guidewire.

In addition, the tips are often made from materials such as Elgiloy® or MP35N® — tough, corrosion resistant alloys that have a tensile strength comparable to 304 stainless steel, which is widely used in the medical device industry. However, these alloys provide better wear resistance than 304 steel, allowing for repetition without device tip failure.

Advantages of Swiss High Precision Machining for Custom Bushings

Medical device manufacturers often use simply machined bushings or cut metal tubing as spacers between metal plates in their devices. Usually, a rivet is passed through the ID of the bushing or tube to compress the plates and hold them together and parallel.

But for the metal bushings used at the tiny tip of catheters and other devices, the tips are often custom Swiss machined to their final shape. That is because tubing is not readily available in custom sizes with Elgiloy, MP35N, and many other specialty materials often used in medical devices.

In addition, the tips may need to be uniquely made so that they can be welded to other metal features in the catheter, such as coils or braids, or embedded in the polymer at the tip.

Sometimes the commercial realities of the supply chain, as well as the limitations of metallurgical properties, create opportunities for Swiss-style CNC metal machining because of the volume and properties that the medical device manufacturer (our customer) requires.

For example, an MP35N bushing that Metal Cutting makes in high volumes for one customer would have been more cost effective to make from a piece of tubing. However, the tube manufacturing process cannot achieve the necessary high tensile strength in MP35N tubing.

The good news is, the rod drawing process is able to yield the required tensile strength, so we are able to Swiss machine the bushings successfully from MP35N rod.

Is CNC Swiss-style high precision machining the method that will achieve the form, function, and features you want for your application? Download our free guide Swiss Machine FAQs to learn more about the advantages and capabilities of a Swiss machine shop.