Science Opens Up Alternatives to Stainless Steel

Stainless steel in its different varieties — including 304, 316, and 316L, among others — is the material that forms the backbone of the medical device industry. However, other metals are important and are becoming even more so.

That’s because as science progresses, it also pushes the boundaries of metallurgy. This, in turn, clears the way for both the creation of new applications and the use of more specialty metals for medical device components.

Alloys That Offer New Options

The development of specialty metals in the form of alloys has allowed the medical device industry to look beyond stainless steel for other suitable materials. For example, MP35N, a nickel cobalt alloy, is often substituted for stainless steel due to the alloy’s useful properties.

With about two times the strength of stainless steel, MP35N can be used to produce tubing with a much thinner wall and a thinner profile. In addition, this high molybdenum content alloy provides additional corrosion resistance.

This smaller yet still very strong tubing is an advantage for applications such as urinary tract procedures.

Another great example of gains in science pushing the medical device market toward specialty metals is the rising use of nickel titanium alloy, also known as nitinol or NiTi, which has excellent shape-memory properties.

Nitinol can be made into a tube and then further cut into a very small stent that completely collapses for easy placement inside the human body. Once placed, the stent returns to the desired form — such as a curve, a U, or some other shape — based on its unique ability to “remember” its original shape.

Nitinol is also used for devices such as endoscopes, giving them a high degree of flexibility and kink resistance.

(Learn more about precision tubing cut from MP35N, nitinol, and other materials.)

Specialty Metals of the Refractory Type

Niobium is one of the refractory specialty metals used in today’s medical devices. Very inert and biocompatible in addition to having valuable properties such as high thermal and electric conductivity, niobium is often used to make small parts of pacemakers.

As a very porous refractory metal that encourages bone to grow and attach to it, tantalum is useful for implants when used in the presence of bone. Tantalum is also used for diagnostic marker bands. However, the material is more often used as a composite due to the element’s cost and rarity.

Tungsten is often used in medical device components, such as the tubing used to perform minimally invasive laparoscopic and endoscopic procedures. Besides providing mechanical strength, tungsten can be used where radiopacity is required, principally in fluoroscopy applications.

With a density greater than that of lead, tungsten can also be used as an environmentally safe alternative to lead as a radiation shielding material. (Learn more in our technical paper, A Comparative Analysis of the Properties of Tungsten for Medical Device Applications.)

The development of medical devices designed to be placed and left inside the human body has led specialty metal fabricators to find new uses for titanium, benefitting from .discoveries such as the following:

- As a very inert material, titanium poses little to minimal risk to the human body when implanted.

- Bone actually grows connections to titanium, allowing it to be used to replace bones that are worn out or otherwise unusable.

Artificial knee joints, hip joints, and other similar uses have probably seen their greatest growth due to the use of titanium and its alloys. These materials are much more compatible for the purpose than stainless steel, which does not mate to human bone.

Applications for Precious Metals

As devices were created to be implanted in the body, the need to carefully track those objects also arose. So, for example, when surgeons place a stent inside the body, they rely on so-called marker bands to verify that the stent is in the right place and the correct shape.

Due to their radiopacity, naturally found precious metals such as gold and platinum became important for their use as marker bands — allowing medical professionals to see where devices are placed in the human body.

However, today’s marker bands may be made of a wider range of radiopaque metallics beyond the usual 90% platinum/10% iridium. For instance, tungsten, which is radiopaque and has a density identical to gold but a far lower and more predictable price point, may be used.

Of course, not all precious metals are as “noble” as gold and platinum. For example, while silver is valued in medicine for its antimicrobial properties, it has to be carefully engineered and is rarely used for medical device applications.

Similarly, copper has antimicrobial benefits for uses such as preventing infection and for hospital sterilization. However, copper does pose thrombogenic concerns, although it has been used in IUDs and, when sufficiently shielded, can be used for signal processing with implants and diagnostic tools.

Specialty Metals That Are No Longer Used

Even as new applications are discovered, there are other specialty metals that are no longer used in medical devices.

That’s because over time, science has uncovered the materials’ incompatibility and even toxicity for humans. As a result, significant questions have been raised about previously popular industrial processes used to enhance device appearance and performance.

For example, chrome coating was once used extensively to make parts shiny, but its use in medical device applications has now been almost entirely phased out. Despite the fact that chromium is an essential trace element and small amounts are necessary to human health, exposure to uncontrolled amounts of plated chromium in medical devices is detrimental.

Of course, there are specialty metals that will never again find their way into medical devices. Years ago, mercury was prevalent, but of course now we know that is a terrible idea.

Sadly, we still have reminders today that lead is another metal that has neurotoxicity effects. Therefore it is not used except — cautiously and shrouded — for radiation shielding.

On the other hand, perhaps one should never say never? While radioactive materials are to be avoided in most applications, the destructive properties of radioactive elements are still harnessed and beneficial in cancer treatment.

Experts in Precision Parts from Specialty Metals

As science and medical technology continue to advance, Metal Cutting will be here to meet the needs of the medical device industry for precision tubing and other parts made from specialty metals.

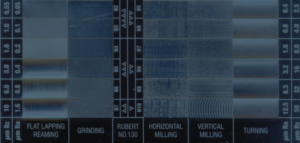

As a precision metal fabricating company, our expert capabilities include very tight tolerance cutting, grinding, lapping, and polishing of all metals for medical device applications. We also provide secondary operations, as well as tungsten and molybdenum products such as wire, ribbon, and rod.

Give Metal Cutting a call for your precision parts needs — and in the meantime, read more about the future of innovation in medical devices in our white paper Metal Tubing in the 21st Century: Who Needs It?