Nitric Acid vs. Citric Acid for Metal Passivation

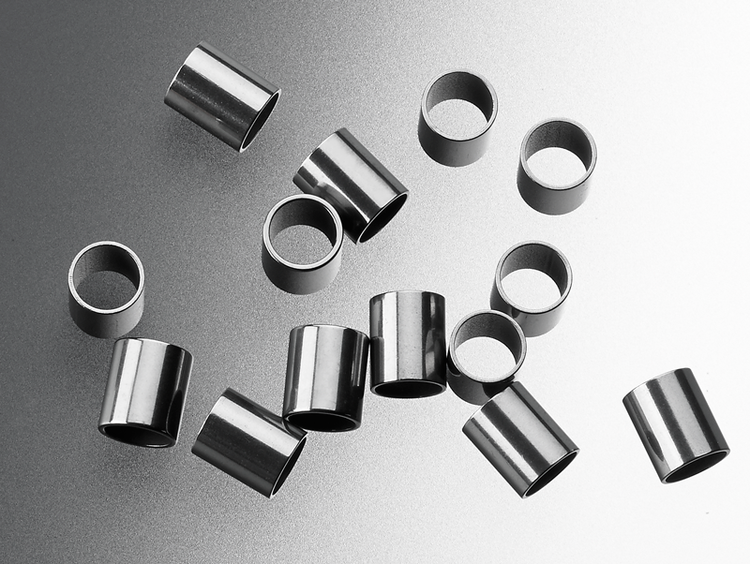

In our industry, the term metal finishing is used in regard to many different processes, but in general it pertains to when, for various reasons, parts need to be made smoother, shinier, duller, or within exact parameters for those characteristics. For example, for precision small parts requiring a smooth surface finish — which is often measured by Ra or RMS, two distinct but related terms — we at Metal Cutting Corporation are highly experienced in polishing or lapping to reach specified degrees of smoothness. Similarly, for parts that need to “mate” with each other and therefore require very smooth surfaces, we can deploy our tumbling or lapping metal finishing services to achieve surface finishes of Ra 0.40 µin (0.010 µm).

There are also times when small parts may need to be made less smooth, such as when a part is going to plastic insert molded. Here, the smoother the surface, the harder it would be for the plastic to adhere to the part and the more likely it would be that the part could slip out of the plastic during use. In these instances, Metal Cutting can expertly “rough up” the part surface through various mechanical methods, such as sandblasting or even CNC machining, to make the surface rougher so the part’s surface is more appropriate for insert molding.

In fact, Metal Cutting offers a complete range of metal finishing services, including more subtle methods such as passivation, which is the removal of an oxide surface layer from the top of certain metals in order to protect them from corrosion.

Why Passivation for Metal Finishing?

Passivation creates a barrier against corrosion by shielding the outer layer of the base metal and making the surface less reactive. Often applied to stainless steel, as well as to other materials, this metal finishing method provides an inert, protective coat that prevents rouging and reduces the rate of corrosion in finished parts.

When metals, especially stainless steel, are going to be used in medical devices and will be exposed to oxygen, humidity, water, or other liquids, after a while the metals can experience rust or other chemical reactions that form where the metal meets the air at the oxide layer. That’s where passivation is used to effectively prevent these reactions, which would pose risks to patients by damaging or contaminating devices such as surgical tools.

Because this method of metal finishing does not change the appearance of the material surface, it is useful in strengthening and preserving the appearance of various metal parts. (Note, however, that passivation is not recommended for parts to be used in aggressive chemical or physical environments.) In addition to its use in medical devices, metal passivation is widely used in other applications where minimizing the potential for contamination and corrosion is critical to the safety and performance of metal parts, for everything from aerospace components to food and beverage processing.

Nitric vs. Citric Acid

Passivation is accomplished by bathing the material in a solution of either nitric acid or citric acid, and over the years there have been many different studies and differing opinions on which one is better. Indeed, the benefits of one versus the other were not always clear, and many industry professionals thought citric acid was inferior for passivation.

However, here at Metal Cutting, citric acid is not only requested more often, but is also the method our metal finishing experts now recommend. That is because citric acid is much safer to use than nitric acid. (Case in point, citric acid is a common food ingredient.) In addition, citric acid is biodegradable and therefore more environmentally friendly. And most importantly, we find that citric acid is equally or more effective for passivation than nitric acid.

In fact, even NASA agrees with us! The space agency sponsored an important study published in 2011, “Citric Acid Passivation of Stainless Steel.” The study concluded that citric acid is a technically sound method of passivation, performing as well as or better than nitric acid.

Whether It’s Passivation or Some Other Metal Finishing You Need . . .

Here at Metal Cutting, we are highly experienced in both citric acid and nitric acid methods of passivation for precision small metal parts, and we offer either one according to each customer’s needs. (Read more about our advantages for metal passivation.) Whether you are choosing between passivation methods or are considering another type of metal finishing for your small metal parts, our experts are here to help, offering advice, assistance, and a quote. Just give us a call. You can also get tips on how to create the best specifications for your parts by downloading our free guide, How to Fine-Tune Your Quote Request to Your Maximum Advantage: Frequently Asked Questions in Small Parts Sourcing.