Advantages of Metal Tube Cutting for Medical Devices

Metal Cutting is always on the lookout for the latest innovations in the tools we use for the Swiss metal CNC machining, precision centerless grinding, mass finishing, and even lapping services that we offer. Yet, these precise machining methods do not begin to capture what Metal Cutting Corporation is all about.

The type of true metal cutting that we excel at — such as cutoff of thin wall steel tubing for medical devices and other precision applications — is actually quite unique. For these very exact and high-volume requirements, our methods of cutting metal tube takes center stage over machining tubes or other available metal tube cutting methods.

Superior Results for Metal Tube Cutting

For hypodermic tubing and other small diameter tubing that our customers are typically looking for, the problem is that — depending on how the process is performed — some cutting processes can produce issues such as:

- Clogging the inside diameter (ID)

- Collapsing the tube ends

- Crushing the entire tube

However, our metal cutting specialists at Metal Cutting Corporation can cut this type of tubing successfully, no matter how small the tube diameter or how thin the tube wall.

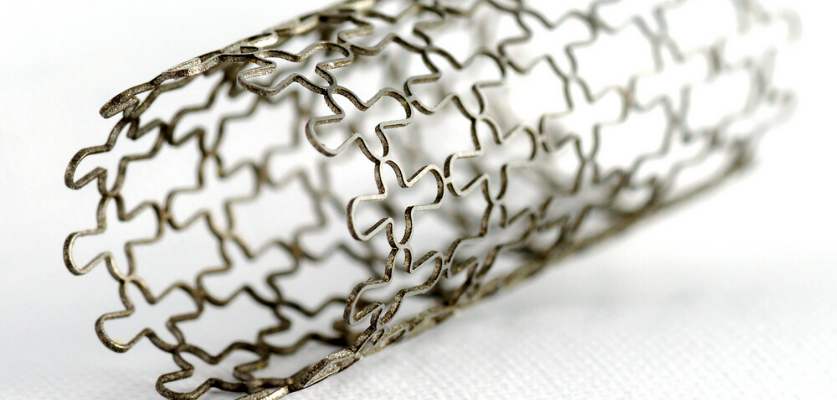

There are ways to use laser cutting for small diameter tubing, such as for medical stents. However, lasers cannot cut a honeycomb or aggregate of parts; the tubes must be cut individually, which is a slow and expensive process.

Metal Cutting has the ability to cut large numbers of thin wall steel tubes simultaneously, and to do it cost effectively and with none of the aforementioned problems. In fact, we like to say if the tubing can be drawn, we can cut it.

For example, we can cut stainless steel tubing with an ID as small as 25 µm (0.001”) and an outside diameter (OD) as small as 75 um (0.003″) — in other words, tubing about the size of a human hair. Most of this very thin wall steel tubing is used in:

- Medical devices, such as for eye surgery or similar treatment methods

- Scientific instruments where small, precise amounts of liquid must be measured and/or dispensed

Other Benefits of Cutting Small Diameter Tubing

Speed and cost are not the only advantages of Metal Cutting’s methods for precision tube cutting. For instance, in addition to being able to cut a bundle of small tubing, when necessary we can cut rotating tubing — cutting only through the tube wall while eliminating the additional stroke time and wheel retraction.

Another important difference is the inevitable heat effect of laser metal cutting. Speaking from personal experience, I know that avoiding the heat of a laser can be a critical issue even in human surgery.

For a procedure I needed a few years ago to remove a polyp from my vocal cords, I was urged to find a surgeon who was skilled in using a cold knife rather than a laser. That’s because the heat produced by a laser could cause permanent scarring on the vocal cords.

Naturally, I went with a cold knife expert, and I am happy to say my surgery was a complete success and my voice is as good as new. Similarly, with Metal Cutting’s methods for handling thin wall tubing, there is no heat affected zone nor resulting deformation or discoloration of parts, as there would be with laser cutting.

Of course, it almost goes without saying that laser cutting is great for achieving extraordinarily complex shapes that are far beyond Metal Cutting’s capabilities. For the types of applications where such intricacy is required, comparing our cutting methods and laser cutting is comparing apples and oranges.

In these cases, the “trade off” of somewhat slower speed and definitely higher cost is simply part of the necessary price for achieving the proper results.

Flexibility in Sourcing Small Parts Tubing

Although we are experts in metal tube cutting, we do not manufacture it. However, Metal Cutting still brings value to our customers with our vendors relationships.

This gives us the ability to source material from any and all of the best vendors of thin wall stainless steel tubing, such as 316, 304, and the hard-to-find 400 series stainless, in welded, drawn, and seamless forms.

Metal Cutting also sources from the leading providers of thin wall tubing made from many other metals, including MP35N, nitinol (also known as NiTi or, in Japan, TiNi) and similar shape memory alloys, the numerous grades of titanium, Kovar, Inconel, and various other nickel alloys.

Cutting Metal Tube That Is Extraordinarily Thin

With our ability to source tubing with the thinnest walls and our unique skills in precisely cutting it to extremely short lengths, observers are often hard pressed to tell that they are, in fact, looking at tubing.

With extremely thin wall steel tubing having an ID and OD so small that they cannot be seen with the naked eye, even wire experts may insist, “That’s too small to be a tube — it must be a solid wire.” Kudos to our tubing manufacturers!

Only when examining the shortest cut parts under a loupe or a microscope can the thin wall tubing characteristics be discerned.

Similarly, at first glance even stamping experts may mistake some of our tiny parts as being stamped or fine blanked rather than thin tubing that we cut to very short lengths. This is because we are able to do so without any deformation to the concentricity of even the most delicate tubes.

Of course, stamping is a very high-speed process that is useful and prevalent in many industrial and consumer applications. However, where deformation and longitudinal grain direction are a concern, our methods for cutting metal tubing are capable of meeting tight tolerance requirements.

Advantages When It Counts

Our proprietary cutoff methods enable us to cut thousands or even hundreds of thousands of pieces of thin wall tubing into smaller parts — and with this capability comes a need for additional skills. Namely, we are also highly experienced in measuring, handling, and counting very small tubing in very large quantities.

That might not seem like a huge issue. However, simply counting 100,000 extremely tiny tubes is like counting individual grains of sand — although, unlike sand, our cut tubing has the benefit of identical sizing due to our ability to maintain very tight tolerances.

Metal Cutting has sophisticated semi-micro counting scales and the skill to use them properly. This ensures that we deliver the correct quantities of small tubing, some of which is so tiny that, together, many thousands of the parts occupy an area as small as a square inch.

Parts Cutoff and Machining Small Metal Parts for Precision Manufacturing

While customers often ask about our small parts machining capabilities, the reality is we offer so much more — especially for manufacturing companies that require cutoff of metal tubing and other precision cut small metal parts.

For information on how to determine which precision cutting method is best for your small parts requirements, download our free guide Choose with Confidence: Comparing 2-Axis Precision Cutting Methods.