Using Copper Tungsten in Resistance Spot Welding for BEVs

Last week, we talked about the use of copper tungsten in the die sinker EDM process utilized to cut parts for a challenging aerospace application. Remarkably, the same copper tungsten can be used for resistance welding, such as the spot welding of wire harnesses. Of course, it is not exactly the same copper tungsten. Not only do the ratios of copper and tungsten change, but so do the ingredients that are added to the recipe to allow it to work optimally, with the longest life and best shape retention.

A Growing Need for Resistance Welding in the Auto Industry

In an age of laser welding, friction welding, and many other types of welding, resistance welding using welding electrodes is a tried and true method. Two electrodes pass a current, and the workpiece that is placed between them is joined. It’s as simple as that.

What can be tricky is when the products to be welded are tiny and there are literally millions of them. Such may be the case with motor, coil, and relay terminals, which sound simple yet are prevalent in automobiles, electronics, semiconductors, and a wide range of other mechanical devices we use every day.

With the ubiquity of solid state electronics, one would think that many of these devices are being replaced or eliminated, but in fact, either they cannot be replicated using solid state electronics OR their use is actually growing. For example, in the auto industry, the innovation of throttle by wire — the technology that replaces traditional physical connections with a wire carrying an electronic signal — is increasing the demand for wiring harnesses that must be spot welded in order to make their connections.

The Welding Challenge with BEVs

In all of the above, we are still talking about conventional internal combustion engine vehicles. So, just IMAGINE how many wiring connections there are in hybrid vehicles and especially, in fully electric BEVs (battery electric vehicles).

Dating back farther than many people realize, the electric vehicles of 100 years ago were remarkable innovation, but typical of the time in which they were developed, they operated at relatively low voltages. In comparison, today’s electric vehicles have to carry us at highway speeds for long distances and with all the modern comforts and conveniences — air conditioning, quality audio systems, and satellite navigation — as well as all the modern safety features.

This requires modern BEVs to operate at much higher voltages — well over even the European 240 volt system, of which it is said (in the United States) that if you get shocked, you might die. Therefore, the quality of the welding becomes incredibly important. Otherwise, a BEV with a poorly spot welded wire harness goes from being an inconvenience to a possible danger.

Copper Tungsten Electrodes to the Rescue

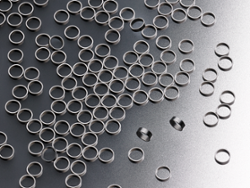

This is where copper tungsten — one of the most popular materials for electrodes used in high-speed, large-volume automated resistance spot welding applications — comes into the picture. As the duty cycle of the wire gets more severe, whether it is a small weld or a large one, and as the voltage passing through the wire rises (requiring a larger weld), the welding electrode material must be able to retain its shape and produce high-volume, repeatable results at higher temperatures.

Simply stated, the more copper tungsten there is in the electrode, the more this goal will be achieved.

Metal Cutting Corporation has been in the specialty tungsten products business since 1967. For tips on tungsten wire or other precision metal fabrication needs, download our free guide to tungsten wire properties and applications!