The answer is not as simple as you’d think!

At Metal Cutting Corporation, we often have people come to us and ask if we do metal fabrication. The truth is, the answer depends on how you define the term. While we don’t consider ourselves a “fabrication company,” we do a lot of fabrication in the sense of producing small metal parts used by our customers to fabricate other larger structures and products across a wide range of applications and industries.

The Big Picture

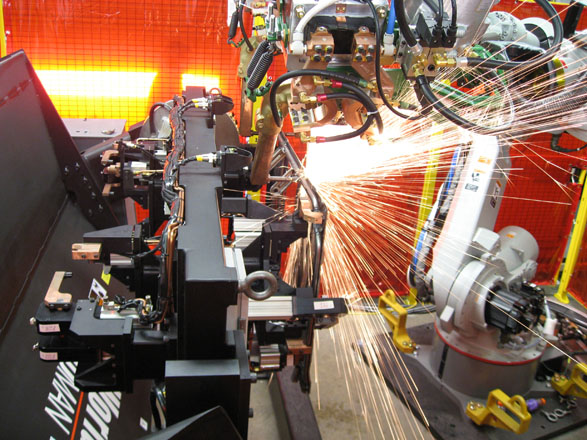

When people think of metal fabrication, they usually think of it as the construction of a single, large metal structure or machine from various raw or semi-finished materials, using processes such as cutting, bending, and assembling. Some common examples of fabrication projects include structural frames for buildings and heavy equipment, as well as parts such as stairs and hand railings for buildings. Fabrication, which may also include processes such as welding, forming, and machining, usually starts with an engineering drawing with precise measurements; those specifications guide the fabrication of the structure or machine and its final installation.

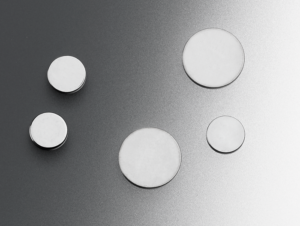

Metal Cutting, on the other hand, does not build one big metal structure. Rather, we produce high volumes of small metal parts — and we do it not by putting things together, but by removing material using precision processes including abrasive cut off, EDM cut off, grinding, lapping, machining, and various finishing techniques such as polishing and tumbling. These “removal processes,” as it were, impart specified tight tolerance dimensions and shapes that may be advantageous for use by other manufacturers in larger, more complex metal fabrication projects.

The Small Parts of Larger Metal Fabrication Needs

At the core of our business, Metal Cutting Corporation specializes in the cut off of tight tolerance, small metal parts for customers with sophisticated requirements. Not “metal fabrication” as it is traditionally defined, our precision cut off and other services nonetheless produce large quantities of small metal parts that are essential to the fabrication of other parts or products, including thousands of components that are used in the fabrication of various medical devices. For example, we not only make tiny leads that are used to connect different parts of pacemakers — we also package these parts to custom specifications, allowing individual parts to be picked out of a form one at a time and then assembled mechanically. This custom packaging enables fabrication to be accomplished as smoothly as possible while also protecting small parts from breakage and other damage.

Often, customers come to us asking for a component to be used in R&D for a larger metal fabrication project. While this application does not necessarily take the best advantage of our high precision expertise and the cost-effectiveness of our high volume production facilities, we can fulfill such requests as long as the part has dimension that is appropriate for our processes. For example, we can cut, lap, grind, machine, or polish a round part if it is a rod with a diameter of 0.003” (0.0762 mm) to 1.00” (25.4 mm). Or, we can provide precision cut-to-length tubing as short as 0.006″ (0.152 mm) with tube walls or IDs as thin as 0.001″ (0.025 mm) while maintaining the tube’s concentricity and without filling or contaminating the tubing ID.

In addition, Metal Cutting offers some as-is industrial products that are utilized in metal fabrication, such as our tungsten electrodes and other specialty refractory metal electrodes, which are used for welding. With our expertise in tungsten, molybdenum, and their alloys, including copper tungsten, silver tungsten, carbide compositions, and heavy metals, our electrodes are great for high-speed, large-volume resistance spot welding manufacturing environments and for die sinker EDM.

The Parts Vs. the Whole

While there are differences between “metal fabrication” in the “larger” sense and what Metal Cutting Corporation does, we can (and do) make many small, tight tolerance metal components that are essential to the success of a variety of fabrication projects. In addition to being experts in precision metal cut off, Metal Cutting provides tight tolerance grinding, lapping, and finishing of all metals, as well as tungsten and molybdenum products. We also offer secondary operations such as bending, angle cutting, and pointing and slotting of small diameter tubes, wires, and rods of all different metals.

For tips on how to engage the right vendor for the small parts you may need for your metal fabrication projects, download our free white paper, 7 Secrets to Choosing a New Contract Partner: Technical Guide to Outsourcing Your Precision Metal Fabrication.