When you think EDM electrode materials, you probably think graphite. Beginning in the early 1950s, when the material first flooded the electrode market, and continuing into today, graphite has been the material of choice for 90% of US-based EDM electrode applications. But what about that other 10%?

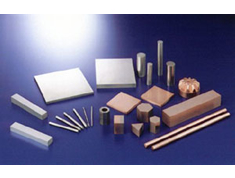

Well before graphite, there was metal. And of the variety of metallic EDM electrode materials, copper tungsten is top of mind for many manufacturers. The unique combination of material properties that results from alloying copper and tungsten is perfectly suited for electrical discharge machining of carbides, where resistance and cutting stability are critical.

So, while graphite prevails in the larger landscape of EDM electrode materials, copper tungsten holds a steady position as the material of choice for intricate geometries, sharp corners, excellent wear resistance, and cutting speeds.

For more on the copper tungsten properties that make it an ideal material for EDM electrodes, download our free technical paper on Copper Tungsten Alloy for EDM Electrodes.