What makes lapping and honing similar and yet so different?

Honing and lapping are often mentioned in the same breath, even though the two are not the same process. In fact, when comparing honing and lapping in the world of precision metal parts, you might say the two are remarkably similar yet fundamentally different.

That may seem like a contradiction, so let’s take a closer look and see why that assessment is, indeed, accurate.

What are lapping and honing?

Lapping is a sanding or polishing method used to create an accurate finish on a flat or domed surface of a part. Honing is a method of internal grinding used to achieve a precise surface finish and shape on the inside diameter (ID) of a tube, bore, or hole.

The honing and lapping processes are both highly controlled. Yet, where they are used and how they are accomplished are very different — and both methods have their own pros and cons.

Why and when are honing and lapping used?

In general, honing and lapping similarities are in the why and when they are used:

- Why? Honing and lapping are both used to achieve a smooth surface and precision dimensions on metal parts.

- When? Honing and lapping are usually performed at the end of the manufacturing process, when some fine-tuning may be required to remove a very small amount of material or finesse the finish on a part.

For example, while Metal Cutting’s double-disk grinding is often the final step in manufacturing, we can add a step and perform lapping for flat, disk-like products such as spacer rings. Here, lapping allows us to achieve greater dimensional accuracy and remove surface finish imperfections, ensuring a close fit between surfaces that need to mate.

What is the difference between honing and lapping?

Honing and lapping differences begin to be revealed if we look at where on a part each process is performed: While honing is used where parts need a precise ID, lapping is performed on an outside flat surface.

And when we look at what each process is, the distinction between honing and lapping is plain to see. That’s because although honing and lapping are both abrading processes, they are accomplished in very different ways.

Honing Process

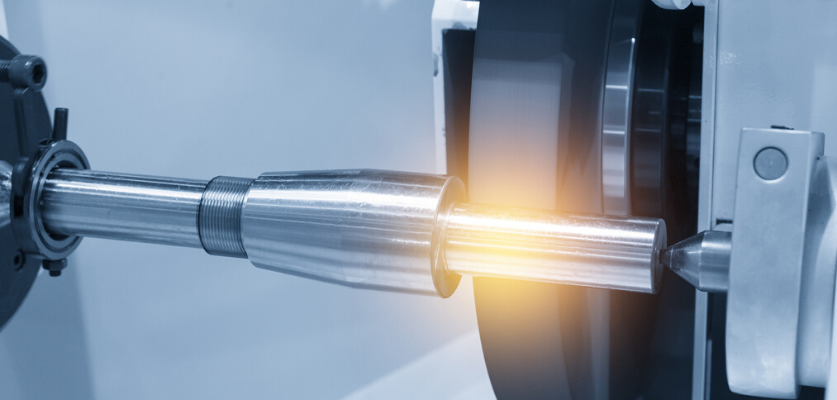

Used to remove material from internal cylindrical surfaces to improve part geometry or produce a finer surface finish, honing is performed at a much slower speed than is typically used in precision grinding.

Unlike internal grinding of metal, which is used to remove thousandths of an inch, honing removes metal in ten thousandths of an inch. That means honing is used for polishing or getting to a very precise surface finish and ID shape.

The cutting action is achieved by a rotating hone, or stone, which is bonded with a very fine abrasive grit and mounted on a metal mandrel. Rather than being clamped in place, the workpiece is fixed to allow floating and prevent distortion that would result in an oval rather than round hole.

The hone is rotated in a controlled path over the surface of the part. In some cases, a machinist might move the workpiece back and forth over the rotating hone, ensuring that the part is floating rather than being pressed against the hone — again, to avoid an oval hole.

With a horizontal honing machine, the workpiece may be held in a self-aligning fixture while the machine controls the speed and length of the stroke. The hone is hydraulically or mechanically expanded until the desired hole diameter is achieved.

In addition, a cutting fluid must be used. The purpose is threefold: to clean small chips from the work area, to cool the workpiece and hone, and to lubricate the cutting action.

Lapping Process

Lapping is used to achieve surfaces that are very flat and smooth, and to finish round work, such as precision plug gages, to very tight tolerances. Flat lapping corrects surface irregularities caused by sawing or grinding, while domed lapping produces a slender uniform shape for lenses and other curved surfaces.

The lapping process is more gentle than honing and removes much less surface material. Therefore, the workpiece should be as close as possible to final size — achieved, for example, through double-disk grinding — because lapping typically removes only 0.0005” to 0.005” (0.0127 mm to 0.127 mm) of material.

Unlike honing, lapping uses fine-grained, loose abrasive particles suspended in a viscous or liquid base rather than a bonded abrasive stick or stone. The lapping process involves passing the workpiece between one or two large, very flat lap plates along with the abrasive suspension.

With lapping, close attention is paid to controlling every detail. This includes the speed of the plate(s), the pressure on the workpiece, the size and type of abrasive used, the feeding method, and the plate temperature.

What are some advantages of lapping and honing?

Lapping can be used on any outside flat surface of parts made from any material. Any size, diameter, and thickness can be lapped, from a few thousandths up to whatever the maximum thickness limit is of a particular lapping machine.

The lapping process itself does not produce burrs, and it can even be used to remove light burrs from a flat surface. Because the parts don’t need to be clamped in place and very little heat is generated, lapping also does not warp parts.

With its relatively slow speed, honing generates very little heat and pressure, allowing for good control over hole size and part geometry. Besides producing a fine surface finish and improving characteristics such as cylindricity, honing is useful for adjusting the alignment of features such as holes or bores.

In addition, the combined rotating and reciprocating motion of honing creates a crosshatched pattern that is ideal for holding lubrication.

What are some limitations of honing and lapping?

Of course, as with other machining and finishing methods, there are limits to what honing and lapping can accomplish.

Compared with other processes, honing is slow and more time consuming, although improvements in equipment and tools continue to shorten hone times.

Honing also requires workpieces and tools to be precisely floated and rotated so that IDs are not distorted. With a very thin workpiece, even the slightest hand pressure could create a slightly oval hole.

As we often say at Metal Cutting, lapping is as much an art as it is a science. While there are general guidelines and recommendations from lapping equipment manufacturers, many variables can still have an impact on success.

So, some degree of trial and error is part of most, if not all, lapping projects.

How do you get the best results from honing and lapping?

Honing and lapping require expertise as well as the equipment and capacity to meet the demands of challenging precision manufacturing.

Achieving the best results from honing and lapping — or from any precision grinding method — depends on choosing a partner with the skills, knowledge, experience, and willingness to make adjustments as needed based on individual project parameters.

In addition, the right partner will work with you to understand your requirements and help you determine the best method (or methods) for your application.

For tips on how to create specifications that will help your manufacturing partner deliver the results you’re looking for in precision metal parts, get our resource How to Fine-Tune Your Quote Request to Your Maximum Advantage: Frequently Asked Questions in Small Parts Sourcing.