How to Pick Your Partner and Get the Results You Need

As an expert in producing small cut off metal parts, Metal Cutting Corporation specializes in meeting the tight tolerance requirements of customers across applications ranging from automotive parts and electronics to medical devices and biotech, semiconductors, aerospace, and fiber optics. We know cut off like nobody’s business, because it’s the core competency of our business.

So, here are some of our suggestions to help you get the results you want for your precision manufacturing needs.

Ask Your Metal Cutting Specialist About Cut Off Metal Expertise

For small diameter cut off metal parts, of course you want metal cutting specialists that can deliver burr-free results and tight (ideally, micron) tolerances. Look for a vendor that has expertise in cutting parts made from the material you want to use, whether it is a non-ferrous metal such as tungsten wire and molybdenum, a ferrous alloy such as stainless steel, one of the latest nickel- and titanium-based alloys, or other specialty metal.

In addition, you want your vendor to excel at high Cpk and Ppk tight tolerance cut off, with experience in complex metrologies, demanding dimensional requirements, and a track record of accurate and repeatable results. Depending on your cut off metal parts and your application, don’t hesitate to ask a prospective partner questions such as the following about their capabilities:

- What is the vendor’s track record on producing parts that are free of burrs and with the kerf that you expect?

- What tolerances can the vendor achieve on the lengths you need? For instance, can they produce length tolerances down to 0.001” (0.025 mm) on very short lengths, such as 0.008” (0.20 mm)?

- Can the vendor hold tight tolerances — such as ± 0.005” (±0.125 mm) — on longer lengths, such as cuts over 6.0’ (2.0 m)?

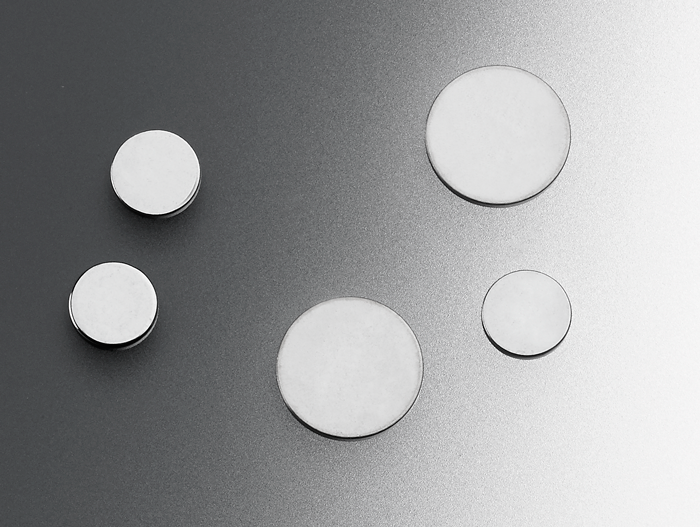

- Can the vendor cut a range of diameters — for instance, from 0.0005” to 3.00” (0.0125-75.0 mm) — to meet your needs for a range of part sizes?

- Can the vendor cut thin tube walls, such as 0.001” (0.025 mm), without deformation?

- Can the vendor cut composites or coated metals without deformation or damage of any kind?

For example, if you ask Metal Cutting about our capabilities in precision metal cut-to-length tubing, we will tell you we can cut lengths as short as 0.006″ (0.152 mm) with tube walls or IDs as thin as 0.001″ (0.025 mm), and we do so without damaging the tube’s concentricity and filling or contaminating the tubing ID. In our precision tube cutting, we can cut the tubing at precise lengths without damaging the coating and while maintaining the tubing’s concentricity and clean ID. We cut to 0.001″ tolerances and can also lap in house and move the tolerance decimal to the left to achieve 0.0001″ tolerances.

Look at Cut Off Metal Equipment for Machining Small Metal Parts

Of course, you want to choose a provider that has the capacity to handle your order volume and deliver the number of cut off metal parts you need. It’s also smart to use a vendor that has a choice of cutting options, equipment, and tools available in house to handle the type of metal you want to use, in the size (or sizes) you need — providing savings in startup time as well as cost.

For instance, Metal Cutting has an extensive inventory of in-house equipment for machining small metal parts, as well as for related grinding, lapping, polishing, turning, EDM, and metrology capabilities. Our proprietary abrasive wheels produce an end “as-cut” finish that is smoother than other cut off methods, for the simple reason that the wheels themselves are basically analogous to fine grit polishing wheels. Despite this, they can even cut off metal that is extremely hard or dielectric while producing this superior as-cut surface finish. This enable us to cut off metal parts in every combination of size from thin wall tubing to hard metals to coated metals to composite metals and everything in between. For pins, probes, and other solid, small diameter cut off metal parts that are needed in high volumes, our in-house EDM process can delivers highly repeatable lengths, without end-deformation, distortion, or delamination, and do so more economically than many other methods.

When talking to potential partners about their machines for cut off metal parts, be sure to ask if their equipment has advanced features designed to enhance precision and the ability to customize the process for your cut off needs. For instance, programmable operation controls provide great flexibility for production setup and increased changeover speed. Features such as computerized cutting speeds and feeds, as well as linear in-feed encoding, can go a long way in helping to maintain process accuracy and hold tight tolerances.

For small diameters and a large number of cut off metal parts, also look for the ability to bundle materials for greater process efficiency and cost effectiveness; for metal tube cutting, the use of mandrels allows for supported precision tube cutting, which prevents burrs and deformation of the end of the tubing. Here at Metal Cutting, we are also able to manage tubes and only cut the tube walls in a way that produces exceptional squareness; in addition, our proprietary material handling eliminates contamination of tubing ID.

Success Is in Picking Your Partner

Clearly, choosing your metal cutting specialist is crucial to obtaining the cut off metal parts you need — and the team at Metal Cutting understands that making the best decision for your needs can mean the difference between success and failure. So, we encourage you to ask all the questions you need to in order to make sure you’re picking the right partner for your business. Because in the end, the right choice will help to ensure you get not only quality, tight tolerance parts, but also responsive, on-time service.

For more tips on what to ask and how to engage the right vendor for your cut off metal parts, download our free white paper, 7 Secrets to Choosing a New Contract Partner: Technical Guide to Outsourcing Your Precision Metal Fabrication.