Table of Contents

Introduction: What is precision metal CNC machining?

For design engineers, R&D teams, and manufacturers that depend on part sourcing, precision CNC machining allows for the creation of complex parts without additional processing. In fact, precision CNC machining often makes it possible for finished parts to be made on a single machine.

The process of machining small parts removes material and uses a wide range of cutting tools to create the final, and often highly complex, design of a part. The level of precision is enhanced through the use of computer numerical control (CNC), which is used to automate the control of the machining tools.

The role of “CNC” in high precision machining

Using coded programming instructions, CNC precise machining allows a workpiece to be cut and shaped to specifications without manual intervention by a machine operator.

Taking a computer aided design (CAD) model provided by a customer, an expert machinist uses computer aided manufacturing software (CAM) to create the instructions for machining the part. Based on the CAD model, the software determines what tool paths are needed and generates the programming code that tells the machine:

- What the correct RPMs and feed rates are

- When and where to move the tool and/or workpiece

- How deep to cut

- When to apply coolant

- Any other factors related to speed, feed rate, and coordination

A CNC controller then uses the programming code to control, automate, and monitor the movements of the machine.

Today, CNC is a built-in feature of a wide range of equipment, from lathes, mills, and routers to wire EDM (electrical discharge machining), laser, and plasma cutting machines. In addition to automating the machining process and enhancing precision, CNC eliminates manual tasks and frees machinists to oversee multiple machines running at the same time.

In addition, once a tool path has been designed and a machine is programmed, it can run a part any number of times. This provides a high level of precision and repeatability, which in turn makes the process highly cost effective and scalable.

Small machined parts and materials

Some metals that are commonly machined include aluminum, brass, bronze, copper, steel, titanium, and zinc. In addition, wood, foam, fiberglass, and plastics such as polypropylene can also be machined.

In fact, just about any material can be used with precision CNC metal machining — of course, depending on the application and its requirements.

Some advantages of precise machining small parts

For many of the small metal parts and precision metal components that are used in a wide range of manufactured products, precision CNC machining is often the fabrication method of choice.

As is true of virtually all cutting and small parts machining methods, different materials behave differently, and the size and shape of a component also have a big impact on the process. However, in general the process of precision CNC machining offers advantages over other machining methods.

That is because CNC machining is capable of delivering:

- A high degree of part complexity

- Tight tolerances, typically ranging from ±0.0002” (±0.00508 mm) to ±0.0005” (±0.0127 mm)

- Exceptionally smooth surface finishes, including custom finishes

- Repeatability, even at high volumes

While a skilled machinist can use a manual lathe to make a quality part in quantities of 10 or 100, what happens when you need 1,000 parts? 10,000 parts? 100,000 or a million parts?

With precision CNC machining, you can get the scalability and speed needed for this type of high-volume production. In addition, the high repeatability of precision CNC machining gives you parts that are all the same from start to finish, no matter how many parts you are producing.

Get some machinists’ tips on how to keep the production of small, complex parts cost-effective in our blog Top 5 Challenges in CNC Machining Services Explained.

In the next section, we’ll take a look at some of the equipment and the processes that are most frequently used in precision CNC machining.

How It’s Done: What processes and equipment are commonly used in high precision machining?

There are some very specialized methods of CNC machining, including wire EDM (electrical discharge machining), additive machining, and 3D laser printing. For example, wire EDM uses conductive materials — typically metals -— and electrical discharges to erode a workpiece into intricate shapes.

However, here we will focus on the milling and turning processes — two subtractive methods that are widely available and frequently used for precision CNC machining.

Milling vs. turning

Milling is a machining process that uses a rotating, cylindrical cutting tool to remove material and create shapes. Milling equipment, known as a mill or a machining center, accomplishes a universe of complex part geometries on some of the largest objects machined metal.

An important characteristic of milling is that the workpiece remains stationary while the cutting tool spins. In other words, on a mill, the rotating cutting tool moves around the workpiece, which remains fixed in place on a bed.

Turning is the process of cutting or shaping a workpiece on equipment called a lathe. Typically, the lathe spins the workpiece on a vertical or horizontal axis while a fixed cutting tool (which may or may not be spinning) moves along the programmed axis.

The tool cannot physically go around the part. The material rotates, allowing the tool to perform the programmed operations. (There is a subset of lathes in which the tools spin around a spool-fed wire, however, that is not covered here.)

In turning, unlike milling, the workpiece spins. The part stock turns on the lathe’s spindle and the cutting tool is brought into contact with the workpiece.

Manual vs. CNC metal machining

While both mills and lathes are available in manual models, CNC machines are more appropriate for purposes of small parts manufacturing — offering scalability and repeatability for applications requiring high volume production of tight tolerance parts.

In addition to offering simple 2-axis machines in which the tool moves in the X and Z axes, precision CNC equipment include multi-axis models in which the workpiece can also move. This is in contrast to a lathe where the workpiece is limited to spinning and the tools will move to create the desired geometry.

These multi-axis configurations allow for the production of more complex geometries in a single operation, without requiring additional work by the machine operator. This not only makes it easier to produce complex parts, but also reduces or eliminates the chance of operator error.

In addition, the use of high-pressure coolant with precision CNC machining ensures that chips do not get into the works, even when utilizing a machine with a vertically oriented spindle.

CNC mills

Different milling machines vary in their sizes, axis configurations, feed rates, cutting speed, the milling feed direction, and other characteristics.

However, in general, CNC mills all utilize a rotating spindle to cut away unwanted material. They are used to cut hard metals such as steel and titanium but can also be used with materials such as plastic and aluminum.

CNC mills are built for repeatability and can be used for everything from prototyping to high volume production. High-end precision CNC mills are often used for tight tolerance work such as milling fine dies and molds.

While CNC milling can deliver quick turnaround, as-milled finishing creates parts with visible tool marks. It may also produce parts with some sharp edges and burrs, so additional processes may be required if edges and burrs are unacceptable for those features.

Of course, deburring tools programmed into the sequence will deburr, although usually achieving 90% of the finished requirement at most, leaving some features for final hand finishing.

As for surface finish, there are tools that will produce not only an acceptable surface finish, but also a mirror-like finish on portions of the work product.

Types of CNC mills

The two basic types of milling machines are known as vertical machining centers and horizontal machining centers, where the primary difference is in the orientation of the machine spindle.

A vertical machining center is a mill in which the spindle axis is aligned in a Z-axis direction. These vertical machines can be further divided into two types:

- Bed mills, in which the spindle moves parallel to its own axis while the table moves perpendicular to the axis of the spindle

- Turret mills, in which the spindle is stationary and the table is moved so that it is always perpendicular and parallel to the axis of spindle during the cutting operation

In a horizontal machining center, the mill’s spindle axis is aligned in a Y-axis direction. The horizontal structure means these mills tend to take up more space on the machine shop floor; they are also generally heavier in weight and more powerful than vertical machines.

A horizontal mill is often used when a better surface finish is required; that’s because the orientation of the spindle means the cutting chips naturally fall away and are easily removed. (As an added benefit, efficient chip removal helps to increase tool life.)

In general, vertical machining centers are more prevalent because they can be as powerful as horizontal machining centers and can handle very small parts. In addition, vertical centers have a smaller footprint than horizontal machining centers.

Multi-axis CNC mills

Precision CNC mill centers are available with multiple axes. A 3-axis mill utilizes the X, Y, and Z axes for a wide variety of work. With a 4-axis mill, the machine can rotate on a vertical and horizontal axis and move the workpiece to allow for more continuous machining.

A 5-axis mill has three traditional axes and two additional rotary axes, enabling the workpiece to be rotated as the spindle head moves around it. This enables five sides of a workpiece to be machined without removing the workpiece and resetting the machine.

Learn more about precision CNC milling here.

CNC lathes

A lathe — also called a turning center — has one or more spindles, and X and Z axes. The machine is used to rotate a workpiece on its axis to perform various cutting and shaping operations, applying a wide range of tools to the workpiece.

CNC lathes, which are also called live action tooling lathes, are ideal for creating symmetrical cylindrical or spherical parts. Like CNC mills, CNC lathes can handle smaller operations such prototyping but can also be set up for high repeatability, supporting high volume production.

CNC lathes can also be set up for relatively hands-free production, which makes them widely used in the automotive, electronics, aerospace, robotics, and medical device industries.

There is hands-free production — and then there is fully automated “lights out” production. Learn about the challenges in our blog Barriers to Lights Out Operation in Precision Machining.

How a CNC lathe works

With a CNC lathe, a blank bar of stock material is loaded into the chuck of the lathe’s spindle. This chuck holds the workpiece in place while the spindle rotates. When the spindle reaches the required speed, a stationary cutting tool is brought into contact with the workpiece to remove material and achieve the correct geometry.

A CNC lathe can perform a number of operations, such as drilling, threading, boring, reaming, facing, and taper turning. Different operations require tool changes and can increase cost and setup time.

When all of the required machining operations are completed, the part is cut from the stock for further processing, if needed. The CNC lathe is then ready to repeat the operation, with little or no additional setup time usually required in between.

CNC lathes can also accommodate a variety of automatic bar feeders, which reduce the amount of manual raw material handling and provide advantages such as the following:

- Reduce the time and effort required of the machine operator

- Support the barstock to reduce vibrations that can negatively affect precision

- Allow the machine tool to operate at optimum spindle speeds

- Minimize changeover times

- Reduce material waste

Types of CNC lathes

There are a number of different types of lathes, but the most common are 2-axis CNC lathes and Swiss-style automatic lathes.

Most CNC Swiss lathes use one or two main spindles plus one or two back (or secondary) spindles, with rotary transfer responsible for the former. The main spindle performs the primary machining operation, with the help of a guide bushing.

In addition, some Swiss lathe machine shops come equipped with a second tool head that operates as a CNC mill.

With a CNC Swiss-style automatic lathe, the stock material is fed through a sliding head spindle into a guide bushing. This allows the tool to cut the material closer to the point where the material is supported, making the Swiss machine especially beneficial for long, slender turned parts and for micromachining.

Multi-axis CNC turning centers and Swiss-style lathes can accomplish multiple machining operations using a single machine. This makes them a cost-effective option for complex geometries that would otherwise require multiple machines or tool changes using equipment such as a traditional CNC mill.

Learn about 5- and 7-axis Swiss machining capabilities here.

Unique advantages of CNC Swiss lathe machine shop

Older style lathes were cam-driven, making them relatively primitive. Today’s Swiss-style lathe with CNC is leaps and bounds better, in both accuracy and efficiency.

On a regular chucker lathe, the part sticks out and is pushed away — that is, deflected — as you start removing material. But on a CNC Swiss machine, the material moves and the tools are stationary, so there is far less deflection.

In addition, a Swiss lathe has both a collet and a guide bushing, to further reduce deflection and machine the parts more precisely. All the action is at the edge of the guide bushing; the correct length of material is fed out, machined, and parted off, then another length of material is fed.

So, with little or no deflection in its machining process, the CNC Swiss-style screw machine provides greater accuracy, precision, and consistency. Learn more about the advantages of eliminating deflection in our blog Deflection and Precision in CNC Swiss Machining.

In addition, compared with other precision CNC machining methods, CNC Swiss-style machining:

- Reduces part handling and labor

- Streamlines setup

- Accelerates cycle times

- Allows parts to be finished in a single operation

- Eliminates the risk of operator error

In the next section, we’ll examine some of the tools and techniques used with precision CNC Swiss machining.

What It Does: What are some common uses for CNC Swiss machining?

The Swiss screw machine has, quite literally, been around for centuries and shows no sign of stopping. You can read about the evolution of the modern Swiss lathe in our blog The Swiss Machine in Today’s Machine Shop.

The modern precision machine shop leverages CNC Swiss-style machining with a wide range of tools to create parts with an interesting array of features and functions, described below.

Drilling

Drilling is a process that is often used in high precision machining to remove material before performing finishing operations such as threading, tapping, boring, reaming, or broaching.

For Swiss-style machining, almost any drill can be attached to a screw machine tool holder, within the size limitations of the machine. The drill is then used to remove material and create features such as through holes, cross holes, and blind holes of various sizes.

The world of drills is so vast, you could write a book on it, and the availability of drills has exploded. Today, there are drills of remarkably small diameters — as small as 0.002” (50 microns or 0.051 mm). Of course, the length and diameter ratios apply, so there are limitations to how deep you can drill with ultra-small diameter drills.

Drills come in a range of sizes and with different types of flutes. Here at Metal Cutting Corporation, most of the drills we use for precision CNC machining are standard, fractional, decimal, wire, and letter sizes.

Certain drills are used for specific processes. For instance, a #7 drill is used to make a hole to tap a quarter-twenty thread inside a part.

Flutes are grooves that can vary in size, shape, and the number on the bit. The purpose of a drill’s flutes is to ease the exit of the chips as the material is being cut. The exception is a spade drill, which doesn’t have flutes because it is used for shallow hole drilling.

Drills are typically made of hardened steel or carbides, some with abrasive features. The point of a drill is typically angled between 118° and 135° (sometimes 145°), depending on the material being machined, with a 118° being the standard angle. It is used on all drills for all materials, usually following a spot drill or center drill application.

Threading (OD & ID)

For the purposes of precision CNC Swiss machining, a thread is a symmetrical radial feature that varies in its pitch. The pitch, or angle, determines the depth of the thread.

In the machining of small metal parts, a threading process is used to create precision threads on the outside diameter (OD) or inside diameter (ID) of the part. There are four methods for producing OD threads:

- Single point threading uses a tool that is ground to the specific angle needed for the thread you want to create; at Metal Cutting, typically we thread at 60° inclusive. The single point tool is fed along the Z axis until the desired depth is met.

- Thread rolling involves feeding the material between (usually, three) die rolls, where the threads are formed rather than cut into the correct shape and depth. Quicker, more efficient, and more accurate than the single point method, thread rolling can also create threads all the way to the shoulder of the part (such as up to the head of a screw).

- Thread whirling, which was invented for surgical bone screws, is complicated and expensive. However, with the proper tools and inserts, it can be used to make virtually any type of thread an engineer can design for medical and other proprietary uses. With the tool spinning at a set RPM and the material also rotating, the threads come out with no burrs.

- Die threading makes threads using a die made of high-speed steel or carbide and having the pitch and diameter of the thread you want to make. Generally, the die is fed over a rotating diameter, usually along the Z axis. Alternatively, a die may be inserted into the holder and used to form threads rather than cut them.

In Metal Cutting’s world of very small diameter parts, ID threading presents a different kind of variable. That’s because we usually don’t have the luxury of a perpendicular tool, due to the extremely small IDs we are requested to tap.

However, in general precision CNC Swiss machining uses one of two methods used to produce ID threads: single point threading and tapping. For ID threads, single point threading is accomplished in basically the same way as described above for OD threading, except in this instance on the ID of the part.

Tapping creates threads using a tool called a tap, which has a specific pitch and diameter according to the threading that you want to achieve. There are three types of tapping tools:

- A form tap forms the material rather than cutting it.

- A plug tap cuts the material (after using a drill) and usually pushes the material through. That means it cannot be used for ID threading in a blind hole.

- A spiral tap is the same as a plug tap, except a spiral tap has flutes for directing chips away rather than pushing them in. This allows a spiral tap to be used for ID threading in a blind hole.

Slotting

Slotting is used for fitting parts together, either by welding or pressing, and is primarily accomplished through the use of an end mill.

Depending on the toughness of the material being machined, slotting may involve drilling a hole and then using an end mill to rough out the desired steps and dimensions. From there, the end mill does a finishing pass to side cut around the walls and complete the slotting.

This is precisely the type of operation for which end mills were created. A drill would never be used to side cut, because the drill will snap and it is just generally a bad technique. The only cutting edges on a drill are at the point of the drill, not on the side.

While Swiss machines can have live tooling where you could mount a spinning cutting wheel (which Metal Cutting knows well from our cutting business), it is usually not ideal for making a slot. And you definitely could not use a grinding wheel to make a closed slot. Because of the radius of the wheel, which wears over time, you’d never be able to have an inside radius of a perfect, perpendicular 90°.

Boring

Boring is anything but boring. It is actually a pretty remarkable technique, where you take an existing hole and expand it to a new, larger, precise diameter.

It begins with drilling or forming a starter hole smaller than the intended finished size. Then a tool called a boring bar is used to open the hole up to the desired finished size.

Like an end mill, a boring bar can be far more precise in these applications than a drill. For example, if you need an ultra-precise large hole — such as a 0.25” (6.35 mm) hole with a very tight tolerance of ± 0.0002” (0.0051 mm) — it would be virtually impossible to drill that in one pass with a quarter inch drill. (Plus, that would be a very expensive drill.)

You could use reaming, which is much faster than boring, to make a precise hole. However, reamers wear out, creating additional issues.

With a boring bar, you have better tool life and the chances of catastrophic tool wear are small. In addition, the machine can be adjusted to ensure the correct hole size even as the tool itself experiences wear.

Reaming

Reaming is done with a tool known, not surprisingly, as a reamer. As noted previously, reaming is faster than boring. However, there are definite downsides to reaming, including the fact that the hole being reamed will get smaller and smaller — and so, less precise — as the tool wears out.

In fact, reaming carries with it the risk of catastrophic tool wear, which can mean two things:

- A broken tool

- Progressive, drastic change in dimension size, which makes it difficult for the production facility to know when the reaming tool is out of specification

Reaming is more commonly used for requirements such as a tight tolerance straight hole that is going through a tube. Reaming will follow the hole previously made by a drill. If the drilled hole is not straight, the reamed hole will also not be straight.

And if you have challenging geometry within the hole that needs to be held to a specific diameter or dimension, boring is the preferred method over reaming.

Polygon machining

Polygon machining is an operation used to create different geometric shapes on a part. It is a milling method that can be used to create a particular shape to mate with or tighten a threaded part.

For example, polygon machining is often used to create the hex (hexagon) shape that is very commonly used as a wrench head. End mills are an ideal tool for polygon machining and are frequently used with CNC Swiss-style automatic machines.

Swiss screw machines are often called on to make small parts such as screws that will need to be moved either by a machine or by a human being using a tool such as a wrench. The top of the screw can be a Torx head, Phillips head, flat head, or many other shapes, including proprietary designs for security.

In the case of a bolt — unlike a screw, where the motion is transmitted on the internal portion of the screw head — polygon machining meets the need for an external shape with a dedicated mating wrench to expert a rotational force. In addition, polygon machining could be used to create a mating part that is an integral part of an assembly.

Broaching

Broaching is mainly used to make geometric shapes on a part for special tool use. An example is a socket-head cap screw with an ID hex used with a hex wrench to drive in the screw. Other examples include the very common Phillips head, a Torx head, and various proprietary shapes designed for security purposes so that the fastener cannot be easily removed.

Broaching is done with a precision ground broaching insert. Depending on the geometry you need, you can buy or custom-make (grind) your own broaching tool.

Rotary broaching is a tool where the material is spinning and the broach spins but stops once it engages with the material. From there, the broach feeds in to remove material to the desired depth and finished geometry.

Deburring

Most Swiss screw machines can be used to do deburring, an important but often overlooked process. Rather than making something, the purpose of deburring is to remove something — namely, to remove unwanted burrs and sharp edges on machined parts.

Deburring a part helps with fit and the accurate measurement of the part. It also aids in preventing injuries such as cuts and splinters in people who will handle or use the finished part.

Why deburr during machining?

In precision CNC Swiss machining, the machinist can program the screw machine for deburring so that there doesn’t need to be a separate deburring operation afterwards.

While deburring on the machine is an additional operation that will increase cycle time, it is almost always faster than doing the necessary secondary operation on the parts after machining. So overall, deburring during machining will reduce the vendor’s lead time for a customer to get the part.

Deburring is an operation that is done after a specific operation is finished during the machining process. This allows the part to be smooth and free of sharp edges. It can also be an intermediate step done because of chip formation that can affect subsequent tool action, such as a chip that will wrap around a drill.

Features to deburr

For the purpose of programming a tool to achieve deburring, a burr means more than just an extra bump hanging on the corner of a part. It can also be a sharp edge created by the machining process itself.

Machining often leaves behind sharp features that need to be deburred, such as at the top of a hole (with a corner feature) or at the bottom of a through hole. Sophisticated deburring techniques can also include ID bottom hole deburring, where you interpolate a tool to break the edge.

How to deburr

In Metal Cutting’s business, we typically utilize our proprietary abrasive cutting methods to cut tubing and a range of hard, soft, and specialty metals without forming a burr at all. However, for parts that are better suited to other fabrication methods, such as machining, we also offer a range of highly effective mechanical deburring techniques.

Because automatic CNC Swiss machining is not an abrasive process, the deburring technique that is used requires running a tool over the area in question. Various tools can be used, but typically the tool needs to have a cutting action — which means removing the burr will yield a chamfer or radius feature.

At Metal Cutting, we generally use a turning tool for deburring anything on the diameter geometry — programming the CNC Swiss machine to automatically do a finishing pass to add a radius or chamfer, depending on the part. (Learn more about radius corners and deburring in mass production.) For deburring holes, we use an angled carbide spot drill, chamfering tool, or other simple tool capable of breaking the edge

In the next section, we’ll look at some applications that benefit from the use of automatic CNC Swiss machining.

How It’s Used: What are some applications for high precision CNC Swiss machining?

Precision CNC Swiss machining is vitally important to a wide range of manufacturing processes, including:

- High volume end-use parts manufacturing, due to the ability to hold tight tolerances and produce a high-quality finish

- Rapid prototyping when emulating high volume production cycle times is critical to the business model

In particular, precision CNC Swiss machining is frequently used where the goal is to produce very small, tight tolerance parts that have complex geometries.

General industry applications

The growing demand for very small, tight tolerance components has ensured the continuing use of precision CNC Swiss machining in a wide range of industries that commonly source parts. This includes electronics, robotics, aerospace, and other markets where the precision of small components is critical to the form and the function of countless end products.

Benefits in medical device applications

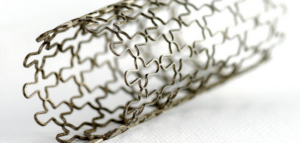

In the medical device industry, precision CNC machining is particularly well suited to a wide range of applications, including surgical tools, catheters, surgical needles, replacement joints, and components for respirators and ventilators.

The ability to Swiss machine a wide range of materials, including plastics as well as exotic metals and alloys, adds to the benefit of its use for the fabrication of medical device components.

The following are just some examples of parts that engineers design into medical devices and that are frequently produced using precision CNC Swiss machining.

Anchors

Also known as bone screws, anchors are used in a variety of orthopedic and orthodontic applications. Often made from titanium, their primary use is to help repair bone fractures by producing compression that holds a bone in place so it can heal more quickly. Anchors are also used in fixation of soft tissue (such as tendons) or attaching teeth or medical implants to bone.

As you would expect, bone screws are cylindrical in shape with a head and thread along the length of the body. They can also have features such as holes and steps, as well as different tips designed to aid in adhesion of the anchor to bone or other tissue. The form and features of the anchors make CNC Swiss machining the preferred method for achieving the proper head, length, diameter, pitch, and tip.

Learn more in our blog Swiss Machining of Bone Screws and Anchors.

Electrodes

Medical electrodes are used to deliver an electrical signal for purposes of cardiac pacing, defibrillation, and neurostimulation systems. Generally made from MP35N® nickel-cobalt alloy due to its electrical properties, the electrodes are usually assembled at the end of a lead and come in contact with tissue to deliver the signal to the treatment area.

Most ring electrodes are simply cut from implant grade tubing. However, the electrodes also require various features that are produced through precision CNC swiss machining and serve purposes such as:

- Allowing the electrode to attach to the delivery catheter

- Creating shaped surfaces that accomplish the required signal delivery

- Providing characteristics unique to a particular device’s design and manufacturer

Learn more in our blog Swiss Machining of Medical Electrodes Made from MP35N®.

Bushings

Customs bushings are sometimes used at the tip of catheters and other medical devices where the tip must rotate at a high rotational speed. The purpose of the bushings is to reduce wear on the end of devices ranging from dental drills to atherectomy devices used to remove plaque from arteries.

Custom bushings are often made from MP35N®, Elgiloy®, or other materials that provide better wear resistance than the 304 grade stainless steel used in so many medical devices. Because tubing is not readily available in custom sizes in these materials, the tips have to be uniquely made. That means the bushings are often machined to the necessary final shape using a CNC Swiss-style lathe.

Learn more in our blog Swiss Machining of Custom Bushings for Medical Devices.

Pull Rings

Pull rings are a crucial component of steerable catheters and sheaths. Located at the tip of the device and connected via wire or cable to a control lever in the handle, the pull ring is what pulls the catheter or sheath tip in one direction or another, allowing a surgeon to guide the tip through veins or arteries.

Many pull rings are simply cut from 304 grade stainless steel tubing. However, if they have specialty features or are made from another material that is not available in standard tube sizes, precision CNC Swiss machining may be required. For instance, when a pull ring is designed with grooves for the wires, OD steps, or slots for polymer flow, it is easier to machine them from solid bar stock.

Learn more in our blog Swiss Machining of Pull Rings for Medical Devices.

Conclusion: Why high precision CNC metal machining?

With its ability to create complex and tight tolerance parts efficiently and cost effectively, it is no wonder that precision CNC machining — and in particular, the Swiss-style automatic lathe — continues to be a mainstay in many machine shops and manufacturing operations.

For a wide range of features, such as threads, holes, and steps, subtractive CNC Swiss-style machining even matches newer additive methods such as 3D laser printing in dimensional end results.

Using an evolving array of tools and techniques, along with the consistency and repeatability advantages of CNC automation, Swiss machining can enable a workpiece to be finished to precise specifications in a single operation, with little or no intervention by a machine operator.

With the ability to work with just about any material and any production volume, precision CNC machining is often the fabrication method of choice for a wide array of manufactured components.

Is precision CNC Swiss machining the right choice for your small parts requirements? Learn more in our free white paper Swiss Machine FAQs: What to Know About the Swiss Lathe and Its Advantages in Precision CNC Machining.