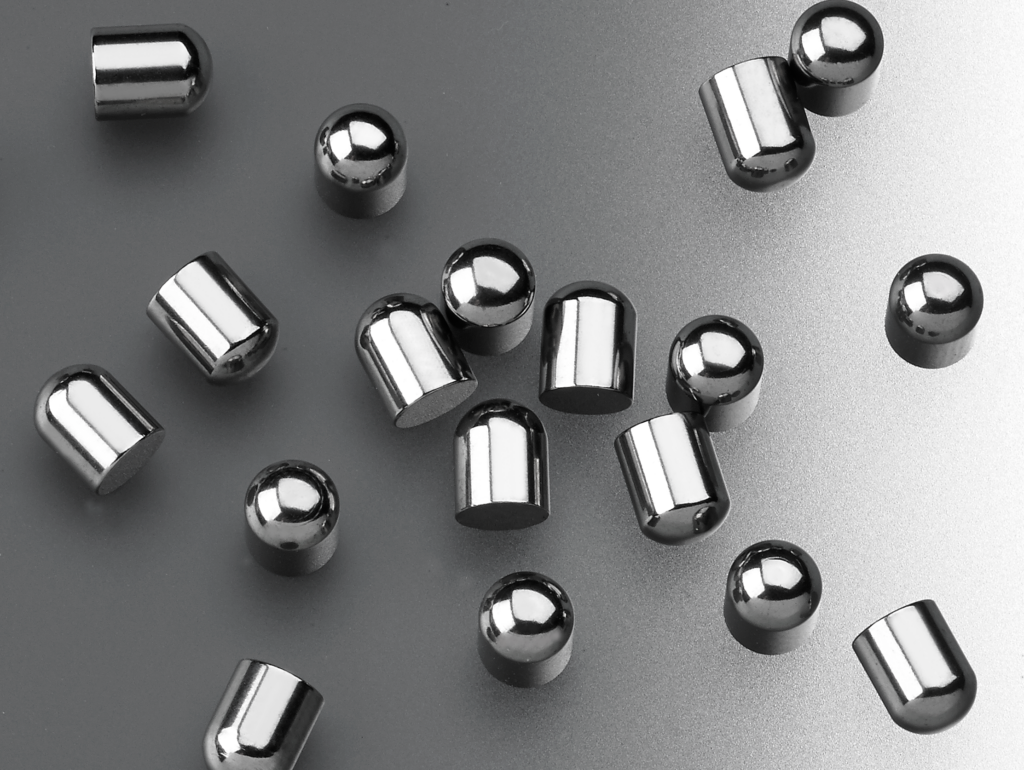

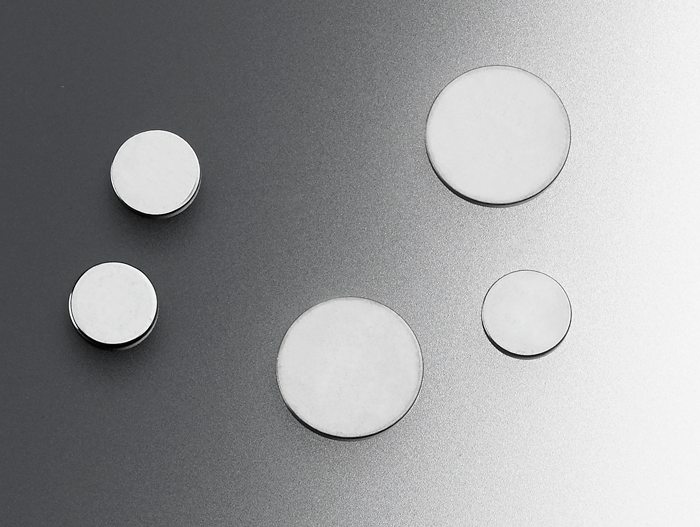

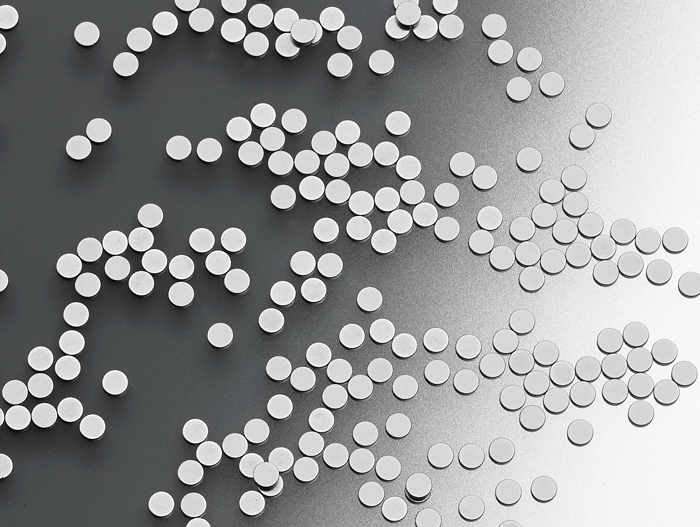

All types of metal, whether hard or soft, precious or base, refractory or ferrous, magnetic or non-magnetic, dense or porous, can be cut to exceptionally tight tolerances. Metal Cutting’s proprietary processes excel at high Cpk and Ppk tight tolerance cutting, and they eliminate the need for any human handling of cut solid metal parts. Process damage such as bending and scratching is also eliminated.

High-Precision Machining of Solid Metal Parts

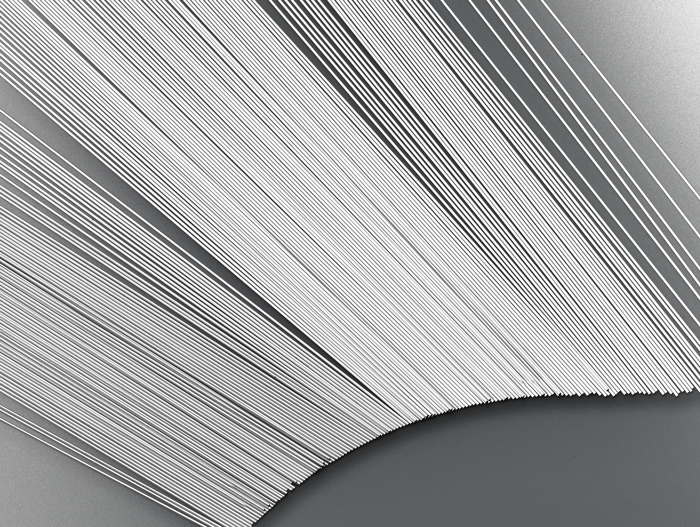

Cutting

End features of squareness and parallelism are tightly held and corner radii as specified, meeting square cut requirements and allowing for subsequent processes to add radii if needed.

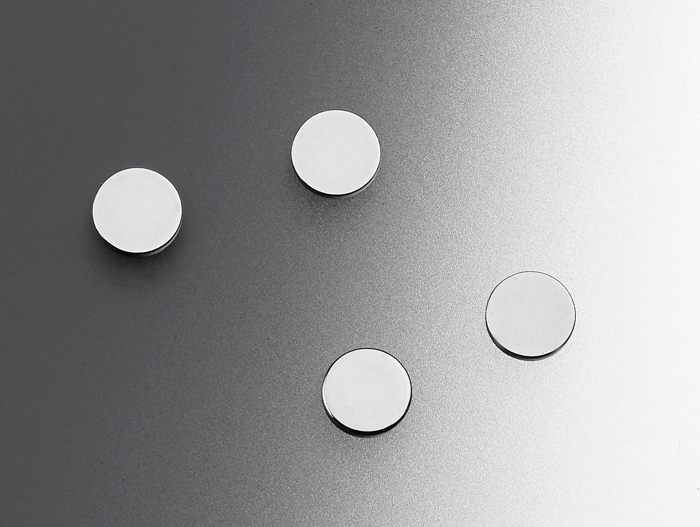

Lapping

Lapping allows us to “move the decimal” to even tighter tolerances and smoother finishes.

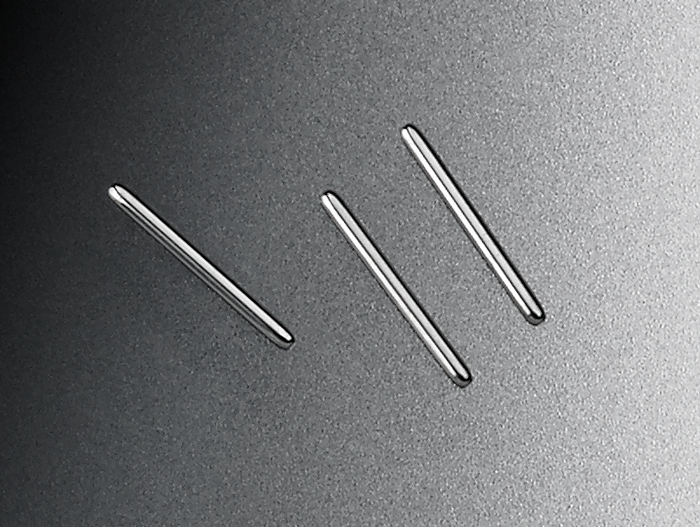

Grinding

We can produce complex profiles, forms, multiple tapers, narrow slots, acute to obtuse angles and cylindrical points from all types of metals.

Polishing

Our polishing techniques can enhance finishes without changing features.

Why Choose Metal Cutting for Precise Machining of Solid Metal Parts

With the many challenges involved in cutting and CNC metal machining small metal parts from different materials, our metal cutting specialists excel at overcoming those challenges across the complete range of material characteristics and all types of metals. For instance:

- Done right, accurate and burr-free cutting of hard metals is easier than cutting soft metals. Knowing which tools to use and what processes and procedures to employ, our methods prevent movement of soft metals, which would otherwise result in the formation of metal cutting burrs that are impossible to remove.

- When cutting a precious metal, such as gold or silver, it is as important to cut the metal parts to tight tolerances as it is to achieve maximum yield — and in both areas, we deliver it all.

- To prevent the oxidation (also known as rust) that can occur with the non-stainless, high carbon family of ferrous metals, we utilize exactly the kind of careful material handling that is required when cutting ferrous metals.

- Processes such as heating or cold working can alter the magnetic properties of metals; however, our equipment does not impart those effects, and the methods we use avoid any unwanted magnetization or demagnetization of metal parts.

- While porosity is not generally associated with metals, coatings on metals can often have different durometers and porosity. Our methods are unaffected by coatings and also any dielectrics; therefore, we can cut coated metal parts with the same accuracy, burr free results and process cleanliness, regardless of whether the coating is hard or soft, polymer or non-polymer.

Measures of central tendency are extremely important for manufacturing customers, and here, too, we excel. That is because while 100% human inspection is possible — and in fact we can, and do, offer it at Metal Cutting — it does carry with it added costs and well known statistical inaccuracies. These include the direct cost of the time and people to complete the task, as well as the expense of purchasing and operating equipment to aid in performing inspections. With human inspection estimated to deliver 80% accuracy at best, there are also indirect costs associated with risks such as quality issues, returned parts or harm to the manufacturer’s reputation and customer satisfaction.

Rather than depending on 100% human inspection, we have machinery capable of measuring dimensional parameters of 100% of your parts with 100% accuracy. In addition, statistical process control is a key strength of our process, enabling us to further minimize or entirely eliminate the need for human handling. With our Swiss machine shop equipment performing the work, our high Cpk and Ppk tight tolerance cutting not only avoids process damage, but also delivers high levels of accuracy, repeatability and reliability.