Metal Cutting is known for our precision grinding, which allows us to achieve sub-micron level tolerances and surface finishes unmatched by our competitors. Our ability to provide these services extends to tubes and wire with diameters almost too small to see.

Precision Grinding Services

Metal grinding has been a core competence for over 45 years and today we offer an extensive range of CNC centerless, plunge, surface, profile, and double disk precision grinding services. We hold extraordinary tolerances, generate specific surface finishes and create highly customized end features. We pride ourselves on the ability to grind complex shapes in difficult-to-machine metals.

Precision Surface Grinding Services

Surface grinding is an important capability that allows us to produce a unique range of products, achieving micron level tolerances and surface finishes down to Ra 8 microinch. Our combination of equipment, knowledge, and experience has made Metal Cutting a leader in the delivery of precision surface grinding services for the most demanding customer needs.

Full-Service Metal Grinding Center

Our full-service metal grinding center contains:

12 Centerless Grinders

4 Plunge/Profile Grinders

6 Surface Grinders

2 Vertical Double Disk Grinders

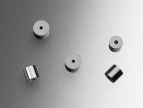

We have two types of through-feed centerless grinders: one design has an open architecture that allows for high throughput speeds and fast change-overs. The other is customized to hold extraordinary sub-micron diameter tolerances. Our in-feed plunge and profile grinding equipment is capable of highly repeatable flats, threads, tapers, shoulders, radii, balls and blivits. We can plunge grind features to diameters as small as 0.003" (75 microns) from tube and wire as long as 12 feet (4 meters). Our micron level tolerance surface grinders have rapid and creep capabilities and using our specialized attachments are capable of end feature profiles up to and including a full spherical end radius. With vertical double disk grinders, we are able to grind high volumes of small metal parts to micron tolerances.

Double Disk Grinding

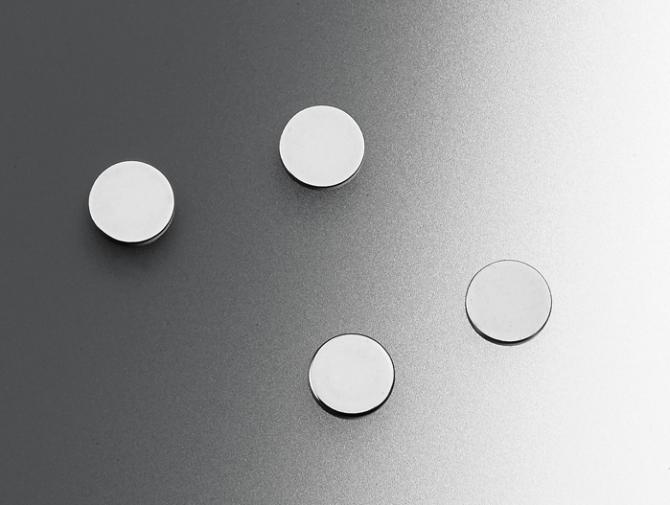

For machining small metal parts, our highly efficient double disk grinding services are unmatched in their ability to produce high volumes of components to micron tolerances. Our vertical double disk grinders not only hold extraordinary dimensional tolerances, but also produce the surface finishes, end features, parallelism, and flatness designed to meet a variety of manufacturing needs.

Custom Metal Grinding Features

Our combination of plunge, surface and CNC profile grinding can efficiently produce complex multi-axis geometries on difficult-to-machine metals with surface finishes unavailable from machining centers. Complex profiles, forms, multiple tapers, narrow slots, all angles and pointed metal parts are produced with speed and accuracy.

Fast Facts About Precision Grinding Services

- Offering unmatched grinding tolerances down to ±0.000020” (±0.5 microns).

- Ground diameters as small as 0.002" (0.05 mm).

- Ground surface finishes as smooth as Ra 4 microinch (Ra 0.100 ㎛) on both solid parts and tubes, including thin wall tubing, long-length components and wire diameters as small as 0.004” (0.10 mm).

- High precision grinding of inside corners and end radii from sharp to full round while holding angle tolerances in the arc seconds to produce profiles, forms, multiple tapers, narrow slots, all angles and pointed metal parts with speed and accuracy.

- Capable of holding and producing geometric features including perpendicularity, squareness, parallelism and flatness—all within arc seconds.

Lapping Services

When you require highly polished part ends, extremely tight length tolerances and extraordinary flatness unavailable by any other production method, we employ our large and unique in-house lapping machines. We can process both tubes and solids using our experienced lapping, fine grinding and flat honing capabilities which allows us to meet your precision tolerance and surface finish requirements.

Precision Flat Lapping Metal Services

For precision lapping of tubes and solids, we have the skills, experience, and know-how to deliver the tightest length tolerances, the smoothest end finishes, and unmatched flatness and parallelism for your metal parts needs. Our extensive inventory of equipment enables us to perform flat lapping, honing, and polishing of all metals, meeting the tight tolerance and surface finish requirements of a wide range of applications.

Flexible Volumes

Whether you have a large or small requirement for highly polished part ends, extremely tight length tolerances or extraordinary flatness, our lapping services can meet your requirements with large lapping, fine grinding and flat honing capabilities. Our capacity may be large, but our specialty is the stress-free high precision centerless grinding of small metal parts.

Specialized Performance

We have three types of lapping equipment, each of which offers specialized performance and easy set-up for small batch fast turn-around. Our double disk grinders have huge throughput capacity and can handle your largest volumes. Solid parts or tubes, including thin wall tubes, can all be precision processed free of heat-affected zones and with significant surface finish improvements.

Fast Facts About Lapping Services

- Our 12 lapping machines hold length and thickness tolerances down to ± 0.0001” (0.0025 mm).

- Our lapping services can achieve a Ra 2 microinch (Ra 0.050 ㎛) end finish on both solid parts and tubes, including thin wall tubing and long length components.

- Custom lapping techniques can correct surface irregularities and achieve exceptional flatness and parallelism.

- Surface metrology is verified by multiple in-house LVDT systems and computerized profilometers